Laser Displacement Sensor in High Demand with Customers Based on the concept of “For all engineers who don’t have time for the hassle” we launched a series of multi-function sensors in December 2024. Its purpose is to help solve the labor shortage in the manufacturing industry and boost engineers’ work efficiency. The sensors can achieve stable detection using just their initial settings and are broadly compatible with a variety of identification applications, including height measurement, tilt detection, and positioning. The sensors offer significant improvements in stable detection, user interface, and overall usability. They are offered at a low price, yet they are packed with innovative features designed to save time and effort for engineers engaged in equipment design, manufacturing, startup, and maintenance.

Moving forward, we will continue to contribute to improved productivity in manufacturing by launching more products like this that meet strong customer demand.

The “ZP-L” sensor launched in December 2024

To ease labor shortages facing many manufacturers, we launched the “Data Flow Controller” in September 2025 to promote the utilization of on-site data. Through repeated dialogue with our customers, we identified that one of the key barriers to advancing DX is the burden of initial investment costs and the increased workload it entails. For this reason, we developed the product with a focus on effortless connectivity and use. This controller can connect various devices within a factory, including those from other companies, on-site and collect data without the need for programming. The acquired data enables the visualization of factory equipment and conditions, and allows for purpose-driven analysis, such as monitoring. It also facilitates timely reporting to decision-makers, contributing to speedy management decisions. Going forward, we plan to offer the product primarily to factories with fully operational existing equipment and to companies for whom large-scale investment in DX is difficult.

The “Data Flow Controller” simultaneously released globally in September 2025

In collaboration with DENSO CORPORATION (DENSO), which aims to create next-generation factories, we jointly developed an AI-equipped visual device and, in fiscal 2024, an algorithm that replicates the high-precision inspections performed by humans. OMRON developed and provided a controller that can sequentially install 15 types of AI with different learning methods and is equipped with 134 new functions. By contributing to the automation of visual inspection, this technology helps improve yield. As a result of the joint development efforts involving extensive discussions between the two companies since the project’s launch in 2022, this initiative was recognized in June 2025 by DENSO with the “Advanced Performance Award ” for its significant contribution to new technologies and products for the future.

Customer testimonial

DENSO CORPORATION

Through the joint development of a vision system equipped with an in-house AI developed by DENSO, we succeeded in creating an inspection algorithm comparable to that of human inspectors. As a result, this contributed to alleviating the shortage of skilled technicians and reducing the number of inspection personnel required. To accommodate a wide variety of products and processes, as many as 134 new functions were developed for this system, significantly improving its usability on production sites.

One example of our efforts to cultivate new customer demand is our collaboration with NVIDIA Corporation. To address the needs of the manufacturing industry, where variable-mix, variable-volume production is required, OMRON is working to improve the efficiency of equipment development by leveraging digital twin technology. By linking OMRON’s control design tools with NVIDIA Corporation’s “NVIDIA Omniverse” platform, which enables workflow and application development in 3D, we have established a system that allows high-precision reproduction and verification of equipment and machinery internals in a virtual space, as well as optimization of settings through the use of AI. This digital twin technology makes it possible to support improvements in productivity at manufacturing sites, including equipment start-up, troubleshooting, and other operational efficiency enhancements.

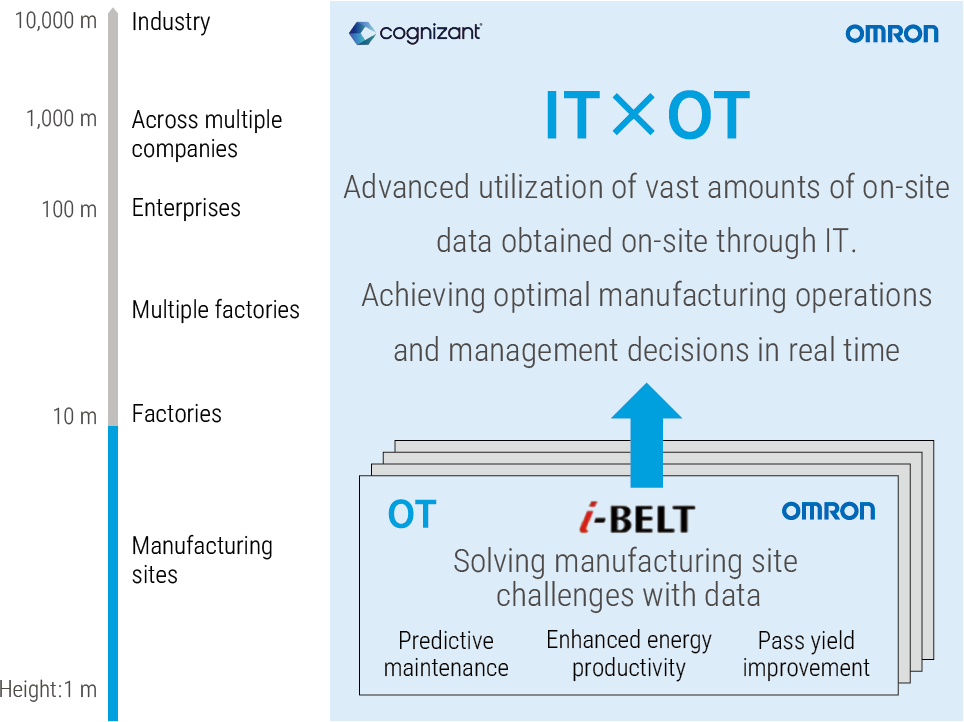

In April 2025, OMRON announced that it had entered into a strategic partnership agreement with Cognizant, a leading U.S.-based IT company, aiming to enhance data processing capabilities and productivity across the entire manufacturing process, thereby strengthening competitiveness. Despite the rapid evolution of IT in recent years, many manufacturing sites have been unable to fully leverage data due to the division between information technology (IT) and operational technology (OT). Factors contributing to this include the siloing of on-site data within individual departments or factories, as well as the technical challenges of linking IT and OT systems. To address these issues, OMRON and Cognizant have jointly developed a platform that integrates OMRON’s control devices, such as sensors, controllers, servo motors, and robots, with Cognizant’s IT technologies (including cloud, AI, and IoT). This enables the provision of end-to-end solutions, from on-site implementation to consulting, for customers across industries such as automotive, semiconductors, electronics, and consumer goods. Through this partnership, we will combine Cognizant’s strong IT solution capabilities with OMRON’s high-quality control devices and on-site data collection expertise to enable the utilization of on-site data not only in manufacturing operations but also in management (See Figure 1).

Customer testimonial

Global Automotive Company

In realizing high-mix, low-volume production at automotive plants, the conventional approach to keep using existing manufacturing equipment and devices has challenges, making it difficult to freely add or modify necessary functions. As a solution for the challenges, we decided to adopt the virtual control platform jointly developed by OMRON and Cognizant. By achieving data aggregation and centralized management from various controller functions used in the existing production processes, the platform enables easy addition of required functions, thereby allowing the construction of systems suited to high-mix, low-volume production. In addition, reducing wiring and additional components leads to cost reductions and improved reliability. We highly value OMRON’s deep understanding of manufacturing sites and its broad lineup of control devices and systems, which made the development of this platform possible. Looking ahead, we expect to expand this mechanism across entire production processes and to benefit from strong global support through collaboration with Cognizant.

By combining the strengths of OMRON and Cognizant, we are bridging the division between IT and OT.

Together, we are creating solutions to be quickly implemented at the production floor from management decisions based on on-site data.

In response to the ongoing transformation in the manufacturing industry—driven by DX initiatives for future manufacturing and the global optimization of production facilities—OMRON is expanding its Automation Centers to address emerging customer needs. In Europe, we established a new Automation Centers in April in Stuttgart, Germany, where numerous global manufacturing companies are concentrated. This facility functions as a value co-creation hub, where customers can experience and validate solutions tailored to their on-site challenges, leveraging OMRON’s advanced technology and applications that combine expertise in a wide range of control devices. In the Proof of Concept (POC) laboratory , customers can conduct verification using various types of robots and demonstration tests under conditions that replicate their actual production environments. In addition, a new Automation Centers is scheduled to open in Bengaluru, India, in October. Through these Automation Centers, OMRON aims to collaborate with customers in identifying manufacturing issues and developing concrete solutions to them toward realizing future visions.