In the manufacturing industry, companies are facing a variety of challenges, such as rebuilding product competitiveness to win in global competition, reviewing production sites to prepare for changes in national policies and geopolitical risks, and shortages of skilled workers. In response to these challenges, the need for factory automation (FA) is increasing more than ever.

In the markets accessed by IAB, although investment in China is entering a correction phase, we expect steady growth to continue beyond fiscal 2025 for the following reasons. These include investment in semiconductor-related markets driven by growing demand for AI and data centers, and expansion of investment in environmental mobility such as secondary batteries, spurred by the increasing adoption of EVs. We will firmly capture business opportunities not only in China but also in Europe, the U.S., and China Plus One markets through IAB, and build a stable customer base for the medium- to long-term growth of the business. In addition, by developing and providing solutions that address challenges in manufacturing, we aim to outpace market growth.

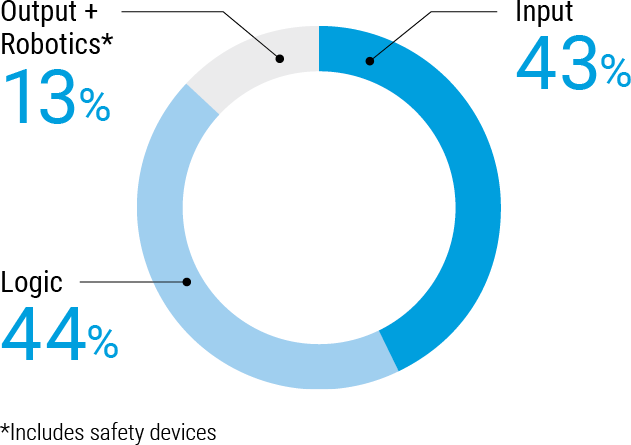

We have a threefold value proposition through IAB that can resolve issues at our customers’ manufacturing sites. To start, our extensive product lineup. We are strengthening our core products, such as various sensors for monitoring equipment status and collecting other information, and controllers that enable high-speed, high-precision control of equipment. Going forward, drawing on the wealth of knowledge that OMRON has cultivated at manufacturing sites, we will further enhance our product lineup to contribute to the progress of manufacturing. Secondly, control applications that are a sophisticated solution for advanced control. At manufacturing sites, advanced production technology is required, such as in semiconductor manufacturing that is characterized by constant technological innovation, as typified by three-dimensional device structures including chiplets, and in the manufacture of rechargeable batteries, which are a key enabler of a decarbonized society. In such environments, we provide control applications created through the combination of OMRON’s product lineup and software technology, which are widely used to help address customer issues. In addition, we have globally deployed experienced application engineers who provide field technical services to implement solutions at manufacturing sites. Together with our customers, we will continue to resolve new issues by leveraging OMRON’s automation technology. Thirdly, the provision of services that utilize on-site data to help resolve management issues. Notable examples are i-BELT and data solutions that integrate Information Technology (IT) and Operational Technology (OT) (see page 23). i-BELT is a service that utilizes on-site data while leveraging customers’ knowledge. i-BELT is highly regarded for its ability to facilitate identification of on-site issues and systematic implementation of improvement activities through consulting.

Under the business vision of “Enriching the Future for People, Industries and the Globe by Innovative-Automation,” IAB aims to pursue both the advancement of industries and the well-being of people at work, thereby contributing to the evolution toward sustainable industries. To this end, we are advancing two major initiatives: reinforcement of the products (components) that underpin our solutions, and co-creation with partners to generate new solutions.

To start, to reinforce our products, we are intensively allocating development resources from across the company to the creation of highly competitive products. In fiscal 2025, we plan to launch 22 models, including sensors and controllers, and in fiscal 2026, a large number of models such as relays. Secondly, we are enhancing our control applications that enable the evolution of manufacturing technology, in line with the needs of industries and customers. OMRON’s field engineers deployed around the world will work at customer sites in advanced technology fields such as semiconductors and EVs, where high-precision control technology is required, resolving issues together with them as our applications continue to evolve. For example, we are collaborating with NVIDIA Corporation on digital twin technology that enables high-precision replication and verification of equipment operation in virtual space, aiming to contribute to improved productivity at manufacturing sites.

In addition to the i-BELT services that utilize on-site data to address issues on a line and plant basis, such as predictive maintenance, zero-defect manufacturing, and energy-saving production, we are creating new IT-OT solutions through a strategic partnership with Cognizant, an IT company with extensive expertise in manufacturing, to serve as a pillar of future growth. OMRON will leverage its extensive lineup of components together with new solutions to resolve customers’ issues, and contribute to the advancement of manufacturing that will support a sustainable society.

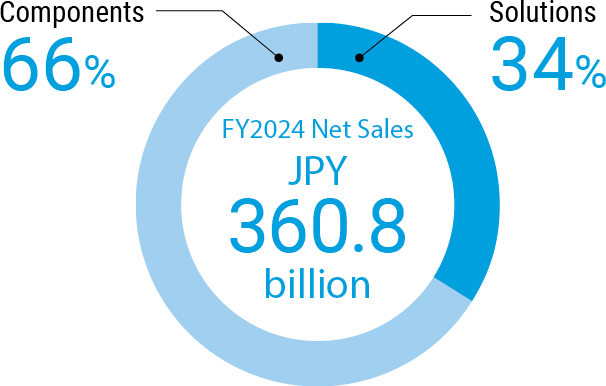

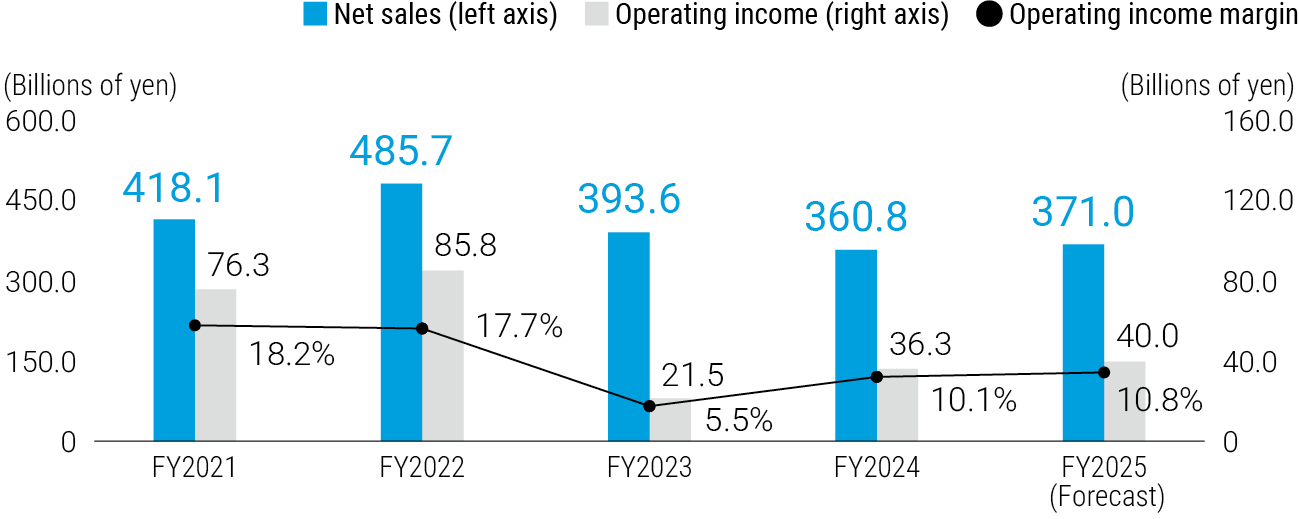

Net Sales for Fiscal 2024

Demand for capital investment in the manufacturing industry was strong in Japan, supported by the semiconductor market, which benefited from investment demand driven by China’s policy to promote domestic semiconductor production. In contrast, demand remained stagnant in China due to sluggish investment in solar power generation and rechargeable batteries, while in Europe and Southeast Asia, investment demand for EVs decelerated. As a result, overall demand showed a sluggish trend. As a result, net sales decreased year on year, partly due to the fact that net sales in the first half of the previous fiscal year had been supported by order backlogs.

Operating Income for Fiscal 2024

Operating income significantly exceeded the previous year’s level, supported by improvements in gross profit margin and the effects of reducing fixed costs through structural reforms, despite lower net sales.