We are Shaping the Future! Showcasing Success Stories as We Innovate for a Sustainable Tomorrow

The Matsusaka Factory (location: Matsusaka City, Mie Prefecture) of OMRON Healthcare (head office: Muko City, Kyoto Prefecture) is the hub of domestic manufacturing and customer service for devices such as blood pressure monitors and thermometers. Under the slogan "All in Half," the factory is working to reduce its Scope 1-3*1 greenhouse gas (GHG) emissions. In collaboration with the OMRON Group's Industrial Automation business, the factory has been working to visualize energy consumption, to streamline the production line, and to control the spatial environment using the in-house data service i-BELT. One year on from the launch of this project, they have devised a clear vision of their ideal future state.

Reiko Suzuki, Production and SCM Strategy HQ, Senior General Manager

Reiko Suzuki, Production and SCM Strategy HQ, Senior General ManagerIn the April 12 media conference unveiling OMRON Healthcare's energy efficiency policy, Reiko Suzuki, Production and SCM Strategy HQ, Senior General Manager, explained: "Some components are still under validation, but I hope that we can serve as a reference point for other companies seeking to reduce their GHG emissions. We are committed to working together to achieve a carbon-neutral society." Below we profile OMRON Healthcare's initiatives thus far, and going forward, to reduce emissions and at the same time drive business growth through these reductions.

*1 Scopes defined by the Greenhouse Gas (GHG) Protocol

ŃĆĆ- Scope 1 (Direct GHG emissions): GHG emissions from sources that are controlled or owned by the reporting organization.

ŃĆĆ- Scope 2 (Indirect GHG emissions): GHG emissions associated with the reporting organization's purchase/use of energy for its facilities and business activities.

ŃĆĆ- Scope 3 (Other emissions): Indirect GHG emissions that occur in the value chain of the reporting organization, including suppliers and users of the organization's products/services.

One of the social issues to be tackled under OMRON's long-term vision, Shaping the Future 2030, is "achievement of carbon neutrality." The OMRON Group as a whole is aiming to reduce its greenhouse gas emissions by 65% (compared to FY2016) by 2030, and to achieve zero emissions in 2050. In line with this aim, OMRON Healthcare and OMRON's Industrial Automation business have joined in committing to the international initiative EP100*2, and have been working to improve the production lines toward a doubling of energy productivity, and to optimize electrical power consumption across the factory.

*2 An international initiative on climate change, involving companies that commit to the goal of doubling the energy productivity of their activities.

ŃĆĆ

Naoki Sone, a Head of Matsusaka Factory

Naoki Sone, a Head of Matsusaka FactoryThe keywords of the Matsusaka Factory's project are "reduce," "create," and "absorb." "Reduce" refers to reduction of energy consumption volumes; "create" is the production and use of clean energy generated through rooftop solar panels and the like. Any remaining GHG emissions will be "absorbed," through cooperation with the local community on conservation of forests that absorb carbon dioxide, including proactive use of local and forest-certified products.

"Reduce," which is the key focus of the current project, does not involve saving energy simply by decreasing the energy use in the factory. The factory's initiative for improving energy productivity involves "boosting productivity while lowering energy consumption," according to Naoki Sone, a head of Matsusaka Factory. "Usually, energy consumption rises if you increase production volumes," Sone explains, "but our aim is to consume less energy, rather than more, even as production volumes rise."

The critical factors that contribute to the realization of higher energy productivity are "time," "space," "distance," and "inventory." All factory employees joined in an all-out effort to devise improvements in these areas.

Visualization system display

Visualization system displayFirst of all, they needed to visualize how much energy was being consumed, where, and when. To do so, they developed an energy visualization system using OMRON's unique factory data utilization service, i-BELT, which is designed to achieve digital transformation in production sites.

General Manager Sone explains: "Previously, we knew the factory's overall energy consumption, but we were unable to identify which building, which workflow, and which production line was using what volume of energy. The energy visualization system created with i-BELT shows us not only our energy consumption, but also simultaneously shows us the volume of goods produced on each production line."

ŃĆĆ

Saori Yoneda, the Matsusaka Factory Production Management Group, Production and SCM Strategy HQ

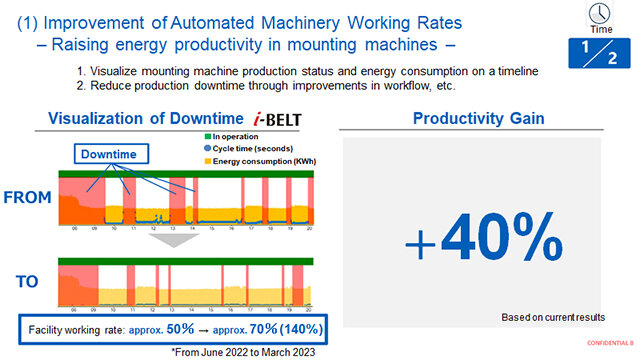

Saori Yoneda, the Matsusaka Factory Production Management Group, Production and SCM Strategy HQOne of the improvements resulting from visualization is better energy productivity in mounting machines. The factory operates many surface mount technology (SMT) devices, so it is crucial to raise their working rate in order to boost productivity. The process of soldering various components onto a substrate is highly energy-intensive. Visualizing the energy consumption in the furnaces used in this soldering process revealed that "energy is being consumed even during production downtime, such as when workers are on breaks and when production equipment is being changed over," says Saori Yoneda of the Matsusaka Factory Production Management Group, Production and SCM Strategy HQ.

(Source: Presentation at media conference, April 12)

(Source: Presentation at media conference, April 12)The figure on the left shows the production status and energy use of mounting machines on a timeline. Energy, shown in yellow, is consumed at a consistent level over the whole timeline. The red portions of the timeline denote production downtime.

Further verifications revealed the potential to achieve 40% higher production volume by ascertaining the periods of downtime and using the standby energy to perform other tasks. However, when a mounter is deactivated its temperature drops, and it takes time to raise the temperature again, resulting in even more downtime. Yoneda appears hopeful of a solution, saying: "We're working on energy control technologies with OMRON Industrial Automation, and now anticipate we'll be able to reduce downtime energy consumption by around 20%."

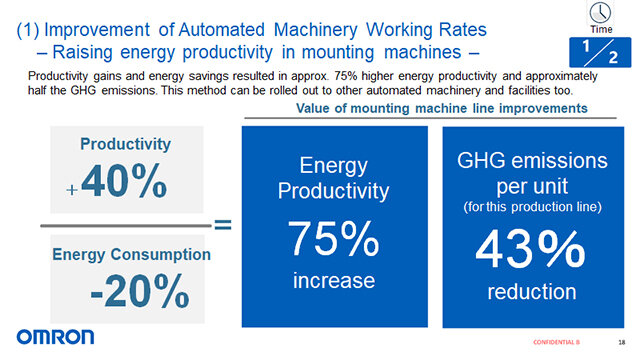

(Source: Presentation at media conference, April 12)

(Source: Presentation at media conference, April 12)The estimate is that energy consumption will be reduced by 20% and production will rise 40%, taking energy productivity to 75% higher than the current level. The team expects that this process will yield a reduction of approximately 43% in greenhouse gas emissions per substrate produced.

ŃĆĆ

In addition to its SMT energy controls, the factory is also working on controlling air-conditioning and lighting. Both on the factory floor and in office spaces, image motion sensors, temperature and humidity sensors, and carbon dioxide sensors are being used to optimize lighting and air-conditioning. Yoneda explains: "We expect to be able to improve energy productivity even further, by controlling the lights and air-conditioning in line with the surrounding conditions and number of people present."

Air-conditioning accounts for around one quarter of all energy consumption at the Matsusaka Factory. The factory comprises three buildings, with an overall floor area of around 8,200 square meters. This means that the factory was consuming around 60kW of energy per square meter. "We knew that if we reduced the space we were using, we could also reduce energy," Yoneda recalls, "but rather than simply squeezing people into a smaller space, we pursued thoroughgoing improvements using OMRON's factory automation (FA) technology and enhancement of the production site as a whole."

They started with the production line for blood pressure monitors, identifying unnecessary spaces and distances one process at a time. This yielded space savings of around 30% of the overall area occupied by the production line. In other words, the amount of space requiring air-conditioning was reduced by 30%, and energy needs consequently dropped by 30% as well. Moreover, efficiency also improved thanks to the reduction in process distances achieved as part of space saving on the production line. "Eliminating redundant movement on this production line raised workability by 30%," Yoneda reports. "This initiative led to energy consumption falling to 70% of the original level, and production volumes and energy productivity rising by 30% and 85% respectively." Furthermore, production line improvements are "expected to enable a reduction of around 46% in GHG emissions for each apparatus on the line."

(Source: Presentation at media conference, April 12)

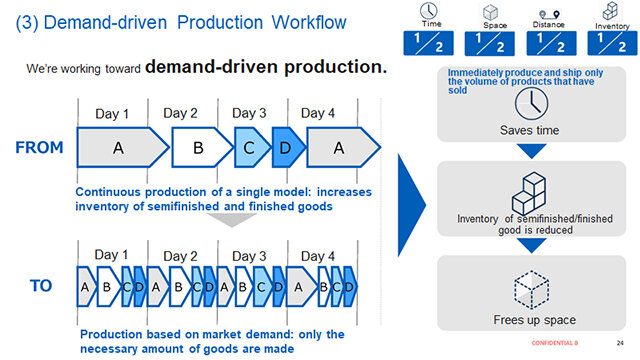

(Source: Presentation at media conference, April 12)In the past, the Matsusaka Factory manufactured consistent volumes of the same product lines in bulk. Now, it has switched to a demand-driven production approach informed by real-time sales data, rapidly producing and shipping only the volume of goods actually sold. The factory no longer holds excess inventory, so can make new use of space formerly dedicated to storage.

Yoneda is feeling confident about these changes: "In November 2022 we were Japan's first manufacturer to join the EP100, and thanks to our initiatives so far, the goal of doubling our energy productivity is already in sight."

The factory's production lines are currently dispersed across three different buildings, but the plan ultimately is to use line improvements and demand-driven production to consolidate the production area into a single building, which will reduce energy consumption even further. The factory envisages using the space freed up in this process for new technology development, and in the future to establish an onsite solar power generation plant. The factory has also declared its future intention to pursue domestic procurement of components currently sourced from China, leading to a reduction in transportation related GHG emissions.

"Some of our projects will be successful, others will not, but we want to share all of them openly as we contribute to the realization of a zero carbon society," says Senior General Manager Suzuki. This new initiative toward carbon neutrality at the Matsusaka Factory might well serve as an important guidepost for Japanese companies, especially in the manufacturing industry, currently confronting the energy crisis and societal demands for decarbonization.