We are Shaping the Future! Showcasing Success Stories as We Innovate for a Sustainable Tomorrow

How two innovators are joining forces on IT-OT convergence to reinvent smart factories for the Industry 5.0 era

They say knowledge is power, but in manufacturing, data is the new currency--and the ability to collect, analyze, and act on it in real time is the key to staying ahead. Today's most advanced factories are no longer just sites of production; they are intelligent ecosystems, where machines communicate, artificial intelligence transforms processes, and entire supply chains adapt dynamically to demand.

The Industry 5.0 era is accelerating this shift, fueled by industrial IoT (IIoT), AI and predictive analytics. The numbers tell a compelling story: The global Industry 5.0 market was valued at $67 billion in 2024 and is projected to grow at a CAGR of 29.7% from 2025 to 2030.1 As factories become more connected, the challenge is no longer just automation--it's about unlocking the full potential of data to drive efficiency, resilience and sustainability at a scale never seen before.

But this transformation comes with urgent challenges. Labor shortages are growing more acute, skilled talent is increasingly difficult to secure, and geopolitical shifts are prompting companies to diversify production bases worldwide. Manufacturing leaders are seeking solutions that not only address workforce constraints but also optimize capital efficiency and drive data-led innovation. The key to success is bridging the shop floor and top floor--connecting real-time production data with high-level business insights for actionable intelligence across entire manufacturing ecosystems.

ŃĆĆ

Recognizing these challenges, OMRON, a leading provider of industrial automation solutions, and Cognizant, one of the world's top professional services companies, announced a strategic partnership on April 8, 2025. Their collaboration merges OMRON's deep expertise in OT with Cognizant's strength in IT solutions, creating a seamless digital manufacturing ecosystem that integrates hardware, software, and data intelligence like never before.

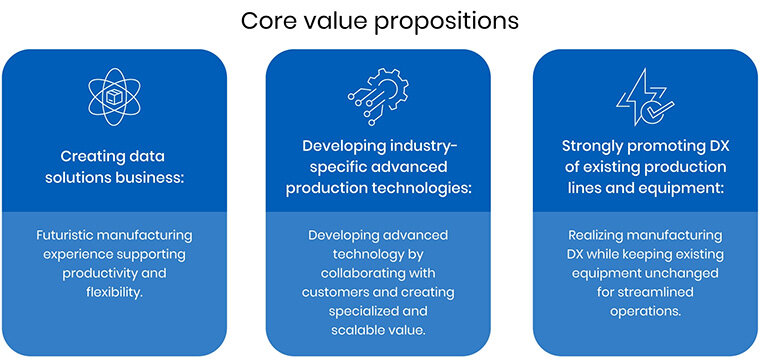

But what's the starting point to finding the right synergies? "OMRON's strength lies in solving real-world production challenges with a combination of advanced hardware, software, and data intelligence," says Motohiro Yamanishi, President of OMRON's Industrial Automation Company. "To seize these opportunities, we will create three new growth strategies, namely - "creating data solutions business", "developing industry-specific advanced production technologies" and "strongly promoting DX of existing production lines and equipment."

"The partnership with Cognizant is our endeavor to accelerate the 'Data Solutions Business' strategy and a big leap towards building an entirely new digital manufacturing model. Through this alliance, we will bring new innovations to customers' site and realize manufacturing in the future", notes an excited Yamanishi.

ŃĆĆ

While OMRON excels at solving factory-floor challenges, the next step is connecting OT with IT-driven insights to improve decision-making across entire production ecosystem. Data is the critical link--and Cognizant provides the missing piece of the puzzle.

"We have a great advantage in providing precision solutions at the device and production line level," Yamanishi explains. "But when it comes to enterprise challenges and supply chain intelligence, integrating IT-driven insights is key. That's where Cognizant comes in."

Cognizant, with its expertise in AI-driven business transformation, brings advanced tools for data analytics, machine learning and supply chain optimization. However, Cognizant faced its own challenge: ensuring accurate, standardized, and actionable OT data. By partnering with OMRON, Cognizant gains access to real-time factory data consolidation through sensors, vision systems, robotics, and PLCs, enabling seamless integration between IT and OT.

"A factory is only as smart as the data it collects," Yamanishi says. "By unifying real-time production data with enterprise intelligence, we are eliminating IT and OT silos and revolutionizing manufacturing."

ŃĆĆ

Through this collaboration, OMRON and Cognizant are tackling some of the most pressing issues in manufacturing today--from skilled labor shortages to carbon-neutral production and eco-friendly manufacturing.

"Our business vision is 'Enriching the Future for People, industries, and the Globe by Innovative-Automation. By promoting automation and empowering human talent in the Industry 5.0 era, we are creating factories that are more adaptive, more efficiment, and more sustainable."

Motohiro Yamanishi

President of OMRON's Industrial Automation Company

A key goal of the partnership is end-to-end supply chain visibility: "We are considering connecting our own factories and supplier sites through Cognizant's IT solutions to achieve Scope 3-compliant manufacturing," Yamanishi explains. "By integrating real-time supply chain data, we can reduce emissions, optimize logistics, and build more sustainable operations globally."

ŃĆĆ

The OMRON-Cognizant partnership marks a major step toward a new era of smart manufacturing. With AI-powered insights, real-time data analytics, and hyper-connected supply chains, manufacturers will be able to respond dynamically to high-mix, low-volume production needs, optimize global factory networks, and improve operational agility.

With an ambitious target of $300 million in cumulative sales over the next five years, the OMRON-Cognizant alliance goes beyond technological integration to pioneer a data-driven future for global manufacturing.

Produced by Bloomberg Media Studios in partnership with OMRON