The OMRON Global Awards(TOGA)

What is TOGA?

The OMRON Global Awards (TOGA) reflect OMRON's commitment to improving society by addressing social issues through our business, guided by the OMRON Principles.

TOGA initiatives are intended to share the stories of how the OMRON Principles are practiced throughout the entire Group across the world to ensure that all employees are aware of and understand the Principles, which are the source of OMRON’s strength, and to expand the circle of empathy and resonance.

What TOGA Will Continue to Value

To ensure that the practice of our corporate principles spreads spontaneously, TOGA emphasizes three key points, with employees at the center:

- Encourage daily work challenges and create a community where these can be shared at any time, fostering empathy and praise.

- Emphasize individual initiative in participation, making it easy for anyone to join without the burden of presentations or selection processes.

- Celebrate employees' challenges together and support the acceleration and expansion of themes.

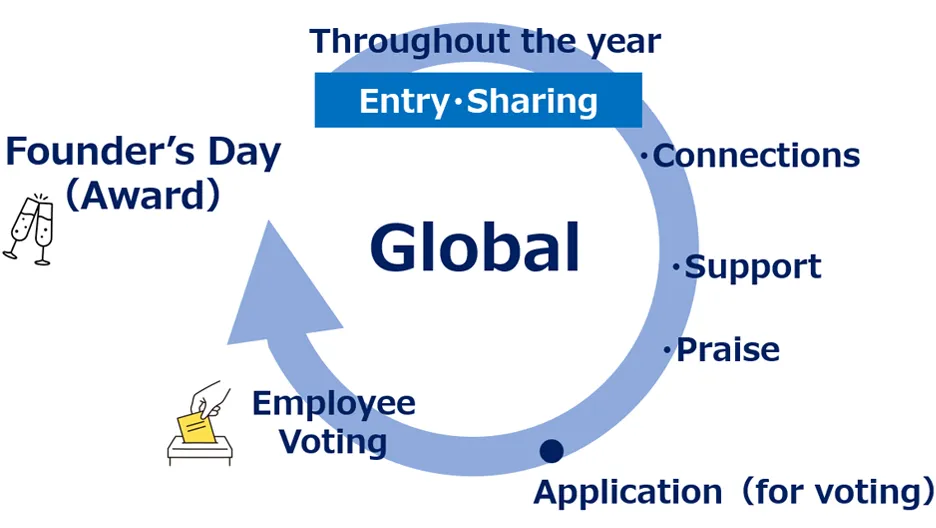

TOGA’s Annual Cycle

In TOGA, we initiate the practice of our corporate principles themes starting from our Founding Day, allowing employees to submit their entries throughout the year. These entries, which reflect their thoughts and efforts towards challenges, are publicly shared within the company. The shared themes spark connections, support, and appreciation among colleagues, further expanding the circle of practice. Subsequently, theme leaders express their intention to participate in the employee voting process, and a role model for the practice of the corporate principles is selected through votes from all employees. The chosen themes are honored at the Founder's Day ceremony, where participants reaffirm the significance of their activities through interactions with management and fellow award recipients.

The Evolution of TOGA

TOGA Begins as the Passion of One Employee

The inspiration for TOGA began in the vision of Irawan Santoso, president of OMRON Manufacturing of Indonesia (OMI), as a means to practice the OMRON Principles in our Indonesian production centers. Santoso' s aspiration for the OMRON Principles ranged far beyond OMRON' s manufacturing plants to include nearby factories and the Indonesian government in a program to employ disabled individuals. At the 2012 event celebrating OMRON's founding, Santoso was honored with the Special Challenge Award for his exemplary practice of the OMRON Principles.

At that time former OMRON CEO Yoshihito Yamada thought: "I believe there are many more stories out there of employees putting the OMRON Principles into practice. We would like to uncover these current and future stories, in order to recognize, support, and share the efforts of OMRON employees." Thus TOGA was born. The circle of empathy and resonance of the practice of the Principles has expanded now outside OMRON as well, and has become a significant driving force for OMRON' s growth.

Evolution of TOGA Operations

Stories of Practicing the OMRON Principles

-

We will create a better society!

Held the 11th TOGA Global Meet -

10th TOGA (The OMRON Global Awards) Global Meet

-

From a Passion to Reduce Marine Plastic Waste was Born an Innovative Packaging Technology

-

Inspiring Employees to Unleash Their Passion for Solving Social Issues

-

Helping Amputees Live a More Fulfilling Life with Active Prosthetics

-

Creating New Social Value Through OMRON's Purpose