3. Creating a New Kind of Interaction Between People and Machines

Meeting the Needs of the Advanced Information Age (1970-present)

Beginning in the 1970s, computer technology quickly spread throughout both industry and society at large. The interaction between computer, communications and control technologies lead to the diversification of requirements for machines. Faced with increasingly sophisticated technological challenges, OMRON focused its efforts on the development of the SINIC Theory, SYSMAC programmable logic controller, fuzzy logic and image processing technology with the ultimate aim of creating a new kind of interaction between people and machines.

1970: Insight into the Future of Society, Science and Technology

Presentation of the SINIC Theory

In the late 1960s, OMRON began to focus on the future development of society, science and technology. Company founder Kazuma Tateisi had a strong belief that the company must have foresight in addition to technological prowess in order to continue assessing and meeting the needs of society, and in order for Japan to become on the world's advanced nations. A study group was formed in 1967 to research future prediction techniques, giving rise to the SINIC (Seed-Innovation to Need-Impetus Cyclic Evolution) theory. The theory was presented at the International Future Research Conference in 1970, where it was enthusiastically accepted.

COLUMN

SINIC Theory

According to the SINIC theory, science, technology and society have a cyclical relationship, in which each area impacts and influences the others in two ways. In one direction, scientific breakthroughs yield new technologies, which stimulate societal advancement. In the other direction, societal needs motivate technological developments and expectations for new scientific advancement. All of these factors affect each other in a cyclical manner, prompting society to evolve.

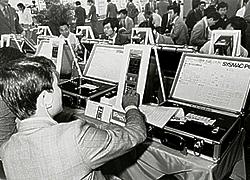

1972: Leading Factory Automation in Japan

Development of the SYSMAC PLC

In the 1970s and 80s, the manufacturing industry saw a shift from mass production of a single product to high-mix, low-volume production. OMRON was quick to detect the emerging need for programmable controllers with a fast processing speed, initiating the development of a sequence programmer for machine tools in 1968, followed by successful development of a programmable sequence controller called "SYSMAC." OMRON programmable sequence controllers not only established a new style of programmable control, but also drove the penetration of factory automation and improved productivity in Japan's manufacturing industry.

1987: Grasping the Intangible

Development of fuzzy logic technology

With the aim of creating harmony between people and machines, OMRON pursued the development of fuzzy logic, which was originally introduced by mathematician Lotfi A. Zadeh, as a next-generation core technology. In developing fuzzy logic, OMRON took on an unexplored area that incorporates ambiguity and subjective human ideas into machine control. OMRON's achievements in this field include the world's fastest fuzzy controller (1987), an ultra-high speed multitask fuzzy controller and the world's fist fuzzy microcomputer chip (both in 1988).

Later, OMRON adopted fuzzy logic combined with various sensing technologies for its control components and many other products, building a base for the development of technologies with more human-like abilities.

COLUMN

Golden '90s Plan

In January 1990, the company name was changed from OMRON Tateisi Electronics Co. to OMRON Corporation. In April of the same year, OMRON set forth a long-term management vision for the decade, called the "Golden '90s Plan." The plan called for the development of businesses tailored to the 21st century in the three key areas: industry, society and daily life. In the industrial area, OMRON focused on microelectronics. We strove to become number one worldwide in components and industry leader in the systems field.

1991: Automating In-line Inspection

Advancement of sensing technology

In the 1990s, the merger of fuzzy logic and control technology spurred the advancement of factory automation. OMRON promoted a shift from manual inspection at the final stage of production to automated in-line inspection by combining sensing and information processing technologies. In 1990, OMRON developed the F300 Vision System, a general-purpose system, which was followed six years later by the development of the VT-WIN, a versatile solder inspection system for use in printed circuit board packaging lines.

COLUMN

Keihanna Innovation Center

May 2003, which marked the 70th anniversary of OMRON's establishment, saw the opening of the Keihanna Innovation Center in Kizugawa, Kyoto. Located in Kansai Science City, Keihanna is at the heart of OMRON's global R&D activities. Through collaborative innovation, we are working to create value by enabling researchers to bring their achievements together. Keihanna Innovation Center was designed to facilitate collaborative innovation in everything from office and lab design to network system configuration. OMRON's new technologies, developed through collaborative innovation, will surely help us realize the "best matching" of machines to people.

2002: Aiming for "The Second OMRON" in China

Establishment of the regional head office and production bases in China

Considering China as a crucial strategic partner that is enjoying rapid economic growth, OMRON has attempted to speed up its business expansion in the Chinese market. Accordingly, OMRON upgraded the status of its regional management center for Greater China to the regional head office in 2002. Based on OMRON's strategy to strengthen its production bases in China, a core electronic components production facility was also set up in Shenzhen in the same year, followed by the establishment of a global production center for control devices in Shanghai in 2006. In 2007, OMRON established a new R&D center in China to promote "collaborative innovation" with local partners.

2009 Addressing Environmental Issues through OMRON Sensing and Control Technology

Full-scale launch of environmental business

As the concern for climate change and other environmental issues rises globally, OMRON set up the Environmental Solutions Business Headquarters in 2009 to make a full-scale entry into the environmental business, with increasing expectations of growth. Along with the supply of individual energy-saving products, such as power monitoring devices, power sensors and DC relays, OMRON also strived to promote solutions intended to conserve and generate energy. As part of this drive, OMRON introduced the "e-watching" CO2 visualization system and consultation service by combining a range of OMRON's environmental devices. In 2010, OMRON also developed a new "ene-brain" CO2 visualization system capable of automatically analyzing areas for potential energy consumption reduction, the first of its kind in the world.

COLUMN

Value Generation 2020 (VG2020)

In July 2011, OMRON announced its new long-term strategy for the decade up to 2020, called the "Value Generation 2020 (VG2020)." VG2020 is divided into two separate stages: the Globe Stage and the Earth Stage. In the Globe Stage (2011 through 2013), OMRON has been striving for growth in the global market, while also strengthening its earnings structure. In the Earth Stage (2014 through 2020), OMRON will work on generating new value from the "Planet Earth" perspective. Through these two stages, OMRON will accelerate business growth and offer new benefits to more customers worldwide.