Know how OMRON collaborated with India’s leading FMCG maker for its Quality Inspection needs in the entire Subcontinent region!

April 01, 2021

FMCG operations require to produce goods to exacting standards to meet the ever stringent regulatory and customer demands. This challenge becomes even more pronounced when the operations are on high speed machines and are spread across multiple locations. To meet these requirements a well-evolved FMCG shop floor demands sophisticated automated inspection solutions. The ones which enable them to produce goods matching the global standards with utmost accuracy without affecting the speed of the multi-layered production process. The inspection solution is required to give the manufacturer the right capabilities to detect flaws in the products, the labels, packaging, barcodes, etc. – all together at the same time – without affecting the production speed without any human intervention.

FMCG operations require to produce goods to exacting standards to meet the ever stringent regulatory and customer demands. This challenge becomes even more pronounced when the operations are on high speed machines and are spread across multiple locations. To meet these requirements a well-evolved FMCG shop floor demands sophisticated automated inspection solutions. The ones which enable them to produce goods matching the global standards with utmost accuracy without affecting the speed of the multi-layered production process. The inspection solution is required to give the manufacturer the right capabilities to detect flaws in the products, the labels, packaging, barcodes, etc. – all together at the same time – without affecting the production speed without any human intervention.

This demanding mandate requires highly synergetic association with an industrial automation solution provider who should score high in the ingenuity of solutions and preferably also have a complete end-to-end solution capability and a futuristic long-term vision going beyond the short-term objectives.

This story of a leading FMCG Maker in India and Omron Automation - India’s leading supplier of industrial automation solutions - reflects these challenges and how they were resolved with mutual collaboration. The project has attained the status of being the largest vision based Quality Inspection project of its kind in the entire Industrial Automation segment in India.

The Big Mandate

Grappling with errors like incorrect printing (manufacturing / expiry dates), cross labeling and wrapped packing, the FMCG maker was spending a lot of unrequired resources and time in managing the cost of rejections and customer complaints impacting its brand image and sales across their personal care product segments.

All this drove the central quality assurance team to urgently implement vision systems to capture and identify the manufacturing date and other printed data, such as price, correctly so that the wrongly labelled and incorrectly printed products do not reach the end-consumers. This was to be achieved by utilizing Optical Character Recognition (OCR) & Optical Character Verification (OCV) technologies and then remove the non-conforming products from the production lines. Additionally, it was also required to capture the OEE data based on this quality inspection. The challenge was compounded by the fact that the manufacturer planned to implement this on over 100 lines spread across 14 locations in the Indian sub-continent simultaneously!

How Omron Came On Board?

OUTSHINING THE COMPETITION

OMRON - The Partner To ‘DE-RISK’ The Project:

The manufacturer had been working with one of their globally empaneled suppliers of vision cameras. However, considering the scale of the project, the maker was extremely keen to de-risk the project and initiated a dialogue with Omron. Leveraging Omron’s strong organizational capabilities and complete product basket, the team presented a project proposal as automation partners who would come on the board as the end-to-end solution providers - taking complete responsibility of execution. This was a unique value proposition that Omron could put together by leveraging its wide product portfolio, a wide channel network and a strong engineering team.

Omron’s engineering expertise and widespread strategic presence across the desired geographies led to the creation of a project proposal which included engineering, supply and installation of the vision cameras, PLCs, sensors, mechanical rejection system and panels followed by after-sales support to be implemented across all the locations simultaneously.

Today, Omron Automation is the total, end-to-end solutions provider for the quality inspection management at these 14 factory locations spread across five countries in the Indian sub-continent; comprising of over 240 vision systems.

The Technical Side – Omron Solutions At Work

- Omron Vision Camera controller for date code and cross packing inspection

- OCR/OCV for date code, expiry code using real time clock function

- Cross packing inspection using barcode/artwork

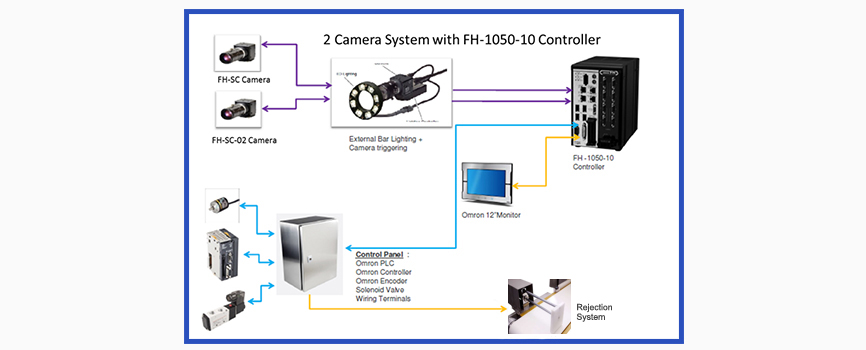

The architecture showing the complete configuration

- Gathering of the right information: The system consists of two vision cameras on each line reading the bar code and checking the cross packing using the vision controller which gathers all information from these cameras and compares it with the original (master) image of an “OK” (correct) Product. The deployed vision system helps in improving the quality by classifying & declaring each product as either “OK” Product or “NG (Not Good)” Product.

- Sifting of the defective products: The “OK” Products remain on the conveyor and move on for further processing whereas the “NG” Product is rejected by an electro-mechanical rejection system (designed and supplied by Omron) and gets collected in a rejection bin for further improvement or recycling after correcting the defects.

- Calculation of oee (original equipment efficiency): The system then calculates the total number of NG Products against the Total Products produced. These calculations aid the manufacturer to know the total rejection percentage – one of the key parameters for calculating the OEE.

- Quality improvements by utilising the data: This data is logged and can be utilized by the management team to take corrective action for further improving the quality of products.

Way Ahead

The story is a very relevant instance of automation players collaborating more with the FMCG manufacturers who are looking for impeccable management of quality control issues with an end-to-end solutions approach in an environment where the production speeds and quality demands are continuously increasing. It is abundantly clear that the manufacturers need an automation partner who has a broad and complete vision empowered with advanced technical know-how as well as availability of local execution capabilities. These are the qualities that were the bed rock of the success of this project. Omron is uniquely positioned to address such requirements. It has the widest product portfolio in the industry and has invested in building engineering and execution capabilities in India over the past several years. The brand is now aiming higher by leveraging this success to expand its presence in the FMCG manufacturing arena by positioning not only its vision solutions but also its other cutting-edge offerings such as the robots and cobots.

.jpg)

.jpg)

.jpg)

Comment