We are Shaping the Future! Showcasing Success Stories as We Innovate for a Sustainable Tomorrow

Junta Tsujinaga Managing Executive Officer Company President, Industrial Automation Company OMRON Corporation *The above titles are current as of March 2023.

Having long supported the evolution of the manufacturing industry with its automation technology, OMRON Corporation ("OMRON") now offers solutions to realize the improvement of "energy productivity" as well. Their goal here is to achieve a higher level of both a reduction in energy consumption and an enhancement of productivity through the integration between data utilization and control technology accumulated over a long period, thus increasing the well-being of workers. For manufacturing businesses to keep producing excellent products, they must contribute to bringing about a decarbonized society as they overcome one social issue after another, such as shortages of skilled engineers and workstyle reform. In a dialogue with younger employees of this electronics giant, Junta Tsujinaga, Managing Executive Officer, concurrently Company President, OMRON's Industrial Automation Company (IAB), shared his passion for enhancing the sustainability of the manufacturing business to enrich the future.

The interviews took place on February 10, 2023.

Tsujinaga: As consumer and social needs diversify, the manufacturing business is growing increasingly sophisticated. It takes not only equipment but also excellent workers to bring high-performance, well-designed products to life. Yet, circumstances surrounding people are only getting increasingly difficult. The working population is declining, and engineers are in short supply. Working practices are changing fast, and work ethics are becoming more multifaceted. As international relations become more complicated and geopolitical risks increase, more and more manufacturers are relocating production sites closer to places of consumption in line with the trend toward "local production for local consumption," which in turn increases labor costs. The manufacturing industry is faced with so many issues, even considering those concerning people alone. That's where automation technology comes in; it not only streamlines and increases the efficiency of production but also achieves higher job satisfaction.

To address these issues, since 2016, we have been proposing solutions made possible by our unique concept of "innovative-Automation," which is designed to achieve the evolution of manufacturing. Comprising three concepts that start with the letter "i," namely, "integrated (evolution in control)," "intelligent (intelligence developed through ICT)," and "interactive (new harmonization between humans and machines)," this initiative aims to advance the state of manufacturing. At present, in an attempt to evolve "innovative-Automation" further, we are taking three different approaches: "automation beyond human abilities," "advanced collaboration between people and machines," and "digital engineering transformation." We combine control equipment, software, and services in a way that fits the circumstances customers are in and optimize them to match the specific needs of individual processes. That's how we innovate manufacturing sites. So far, more than 3,500 companies across the globe have adopted the innovative-Automation concept, and we have offered more than 250 solutions. As a result, this business has grown to account for 35% of IAB's sales, which gives us reasons to believe that we are of service to our customers.

"OMRON is in the manufacturing business, too. I believe that the technology and know-how cultivated in our pursuit of better manufacturing should be of use to our customers in this industry." (President Tsujinaga)

"OMRON is in the manufacturing business, too. I believe that the technology and know-how cultivated in our pursuit of better manufacturing should be of use to our customers in this industry." (President Tsujinaga)As private enterprises find it urgent and imperative to fulfill their environmental responsibilities, including contributions to a decarbonized society, we are providing solutions that enhance "energy productivity," which are designed to achieve both advanced production and environmental responsiveness at a high level. Now, "energy productivity" is an indicator with energy consumption as the denominator and value-added, such as productivity and quality, as the numerator. We aim to build a production system that decreases the denominator and increases the numerator.

Needless to say, every manufacturing business is keenly aware of the gravity of energy issues. For example, making it a rule to turn the lights off in unused rooms and adjust the air conditioning or saving electricity costs to lower the basic cost of running a plant. These are all part of everyday practice at nearly all Japanese companies, but it takes a huge amount of investment to raise the bar. Of course, you could serve society by being friendly to the environment, but unless you supply cost-effective products that satisfy consumers, the size and speed of investment that you can make as a business manager will be subject to change. Hence came the concept of "energy productivity," which encourages decreasing the denominator and increasing the numerator so as to facilitate bold investments.

We began efforts to enhance energy productivity in 2011 at our plants, accumulating skills and know-how to improve both the denominator and numerator. IAB is a manufacturer for manufacturers, so to speak. I believe that any manufacturing business of any sector the world over will empathize with the achievements and successful experiences that we have had in our pursuit of better manufacturing.

In fact, this concept is becoming a trend throughout the world. For instance, a UK-based environmental non-governmental organization (NGO) organizes the EP100, an international corporate initiative participated in by companies with the goal of doubling the energy productivity of their operations. In November last year, OMRON became the first Japanese manufacturer to join this initiative, announcing our commitment to doubling the energy productivity of our operations by 2040.

ŃĆĆ

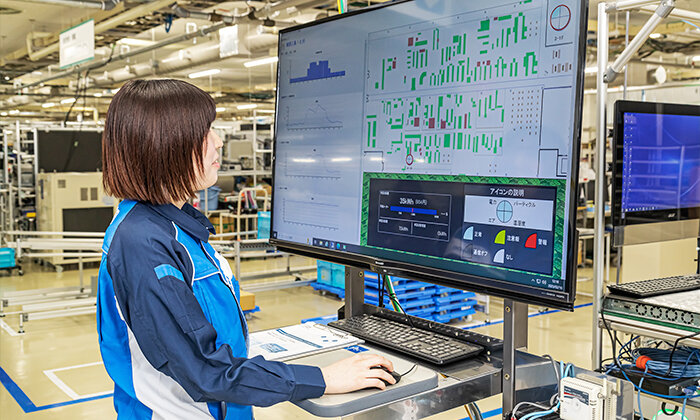

Tanaka: At the Ayabe Factory I'm affiliated with, we promote high-mix, low-volume production of a diverse range of sensors for production equipment. Quality and production efficiency of the sensors are critical as they determine the performance of equipment. To reduce energy consumption while enhancing these parameters, we have introduced OMRON'S proprietary "Environmental Andon System" that can visualize the link between progress in production and energy consumption, using graphs and color coding. The system's large-sized monitors installed in the factory allows sharing of the information not only of the factory overall but of each process. If we are consuming a bit too much energy overall, we can track its cause down to the level of individual pieces of equipment.

Environmental Andon System's large-sized monitor at the Ayabe Factory

Environmental Andon System's large-sized monitor at the Ayabe FactoryThe job of checking the information on the monitors is left to each process manager. Since the monitors can be found on every floor, other employees can see the status. One of the key points of visualization is that it allows everyone to share the same mindset, regardless of their affiliations and the roles they are supposed to play. Without this first step, you cannot expect to improve the shop floor effectively. Many from other companies who toured our factory said that they were interested in what the Environmental Andon System can do. One person commented, "Up to now, we have been focusing on energy conservation only. I was all the more impressed because of this."

Tsujinaga: The Ayabe Factory is among the most advanced of IAB's factories in this regard. Its energy productivity has increased 1.6 times over the past ten years, which they should be quite proud of. Generally speaking, when a factory ramps up its production capacity, energy consumption is liable to rise as it involves increasing equipment. Or they may introduce high-performance yet energy-guzzling equipment. This being the case, you cannot expect to even maintain the value of comparison at 1.0 through efforts such as simply turning off the lights in the factory.

If you find it difficult to make an investment decision when you focus on energy conservation only, you may find it easier to make such a decision if you take a broader perspective to take energy productivity into account. From management's point of view, both social contributions and combatting environmental problems are essential requirements. More recently, as people become increasingly aware of the environment, manufacturing businesses are coming under closer scrutiny from consumers and other stakeholder groups. No matter how good the performance or quality of your product is or how environmentally friendly it may be, you cannot expect support for your business activities if you consume too much energy and thus burden the environment during production or transportation.

Meanwhile, those on the manufacturing sites are charged with the mission of manufacturing products efficiently with the minimum number of defects. Unless they can reduce the environmental burden and increase productivity at the same time, they will have trouble allocating their management resources.

We have begun proposing solutions to enhance energy productivity in Europe and North America. Now that we have announced our commitment to EP100, we will take the offensive in regions that are highly sensitive to the environment and energy problems.

ŃĆĆ

Okuyama: My job is to propose solutions geared toward advanced production and energy conservation to manufacturing businesses in the Chushikoku area. The project I'm involved in lately is with Okayama Murata Manufacturing Co., Ltd., a member of the Murata Manufacturing Group, for enhancing the energy productivity of their clean rooms. More specifically, they have just introduced our i-BELT on-site data utilization service to get hold of the current situation and challenges of their factory. As Internet of Things (IoT) technology is here to stay at manufacturing sites, connecting everything to the internet, it has become possible to acquire all sorts of data. So, roughly speaking, we are identifying and acquiring data that we think will help solve issues, analyzing them to work out improvement plans, and resolving on-site issues by introducing solutions, such as collaborative robots that embody our innovative-Automation concept.

"I find it challenging and rewarding to put myself in customers' shoes to address their issues together" (Okuyama)

"I find it challenging and rewarding to put myself in customers' shoes to address their issues together" (Okuyama)At the same time, we are trying to share the same recognitions about the enhancement of energy productivity with our customers. This is because it would be hard to achieve the ambitious goal of realizing a decarbonized society if we don't unite with the same mindset. In this sense, I find the example case at the Ayabe Factory very handy. We talked honestly to our customers about conflicts among employees that occurred in the course of our attempts and that we worked tenaciously to overcome them. Then, the customers realize that we are not another consulting service ignorant of what's happening on the shop floor and put trust in us, feeling they are in good hands.

When I do the rounds in my area, I can see that their interest in environmental measures and productivity enhancement has begun to grow since last year. It is indeed a challenging and rewarding task to put myself in the customers' shoes and work on their issues.

Tsujinaga: Ours is a B2B business, and we mainly serve those at the manufacturing sites. Because of this, we sometimes find it difficult to communicate to those outside the company how our business activities are related to social contributions. That said, I take pride in the fact that we are connected to society through industrial development, as we believe that helping our customers improve their production activities will lead to the betterment of end-products that are delivered to consumers.

With the recent addition of new perspectives, such as the development of a sustainable society, the environment, and energy, I think it is safe to say that many understand the raison d'être of our business activities. I hope that this emerging trend will give as much satisfaction and joy of work as possible to younger employees, who will shape the future.

Tanaka: The products we manufacture are used in the next stage of manufacturing, which in turn are utilized by yet another manufacturer, until the end product is delivered to society. Once we become aware of this seamless connection, we get motivated to manufacture as many superior products as possible and have them used by someone. I feel the same for productivity improvement. To have others emulate our improvement cases is to have our ingenuity recognized, and I'm always conscious of this as I work.

"Being aware of the connection with society, I get motivated to manufacture as many superior products as possible" (Tanaka)

"Being aware of the connection with society, I get motivated to manufacture as many superior products as possible" (Tanaka)ŃĆĆ

Tsujinaga: I believe that the key to building a well-designed, vital organization is to provide all employees with opportunities to feel rewarded and satisfied with their respective jobs and feel connected with the creation of a better society. Because employees of different functions having the same direction is the basis on which such feelings can be shared, the importance of the corporate principles cannot be stressed enough. At OMRON, our Mission "to improve lives and contribute to a better society" is the very source of the unifying force for employees. To coincide with OMRON's long-term vision, "Shaping the Future 2030," IAB established its business vision, "Enriching the Future for People, Industries, and the Globe by Innovative-Automation." This is also an attempt to align employees' work orientation. The organizational strengths thus enhanced exercise a positive effect when we get to make proposals to or co-create with customers.

Okuyama: It is no exaggeration to say I chose OMRON entirely because of its Corporate Principles. I always come back to the Principles when I am at a loss wondering what I should do as a sales rep or how I should engage with customers. My senior colleagues and supervisors, too, treasure the OMRON Principles, which I think have penetrated throughout the company.

Tanaka: Every year, OMRON organizes The OMRON Global Awards (TOGA), which commends employees' initiatives to practice the OMRON Principles, thus unearthing and sharing various cases. OMRON employees become involved in one way or another, and so this annual celebration helps to spread the OMRON Principles throughout the organization, fostering the growth of employees through recognition of their efforts.

Tsujinaga: No manufacturing business can constantly respond to changes in society, anticipate the latent needs, and keep creating value, without diverse human resources playing active roles. I'm hoping to work hand in hand with like-minded younger employees, like Tanaka-san and Okuyama-san, so that we can contribute to the creation of a better society. Human capital management is gaining a lot of attention these days, and I believe that employees' happiness adds to the vitality of a company. By "people" in IAB's business vision, we mean not just the general public but OMRON employees as well. OMRON is a company that allows its employees to exhibit their strengths and individuality immediately after joining the company. I expect to see more employees take pride in what they do, which in turn helps to increase recognition of the OMRON brand.

We are also open to partnering with other companies in creating innovation driven by social needs. With a mountain of social issues before us, including the realization of a decarbonized society, companies are facing more and more challenges. I don't think that the existing technologies and products are enough to address all such issues, and so we must collaborate with outside companies or assimilate new technologies and knowledge. To create a better society, we will simply keep doing what we should do, going forward.

Attendees (from left)

Attendees (from left)Aya Tanaka

Industrial Sensors Group, Production Dept. 1, Ayabe Factory, Manufacturing and Supply Chain Management Division HQ

Joined OMRON in 2018. Applying her knowledge in information engineering gained in university, she has been mainly involved in the automation of production equipment at the Ayabe Factory, where high-mix, low-volume production is performed. Assigned to the Industrial Sensors Group in 2023, she is currently responsible for production processes and quality control of photomicro sensors, which use light to detect locations of objects.

Shota Okuyama

Chushikoku Sales Group, Sales Division 2, Sales & Marketing Division HQ

Joined OMRON in 2020 to seek a position at a company where he can work for the good of society. At his first assignment in the Nagoya Sales Office, he was responsible for the automobile industry, and in his second year, he was involved with rechargeable battery-related companies at the Osaka Sales Office. Since being transferred to the Okayama Sales Office in April 2023, he has been working with Okayama Murata Manufacturing to enhance their energy productivity.