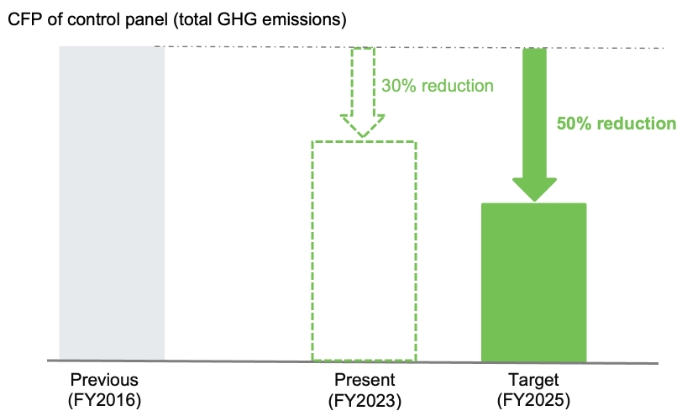

Omron reduces environmental impact by lower carbonation through comprehensive lifecycle of control panel Aiming for half CFP from control panel by FY2025

- June 12, 2023

OMRON Corporation (HQ: Shimogyo-ku, Kyoto; President & CEO: Junta Tsujinaga) will become the first control components manufacturer*1 to quantify the carbon footprint*2 (CFP) of control panels, with an aim to reduce it in half (compared to FY2016) through its products by FY2025. Omron will start this lower carbonization as a Green-Concept from June 2023 and work to develop greener control components and components environmental impact data as well.

CFP (carbon footprint) calculated by OMRON based on international standard ISO14067 to quantify the control panel’s environmental impact as CO2 equivalent. This calculation uses the life cycle assessment approach, which evaluates a product’s environmental impact across its life cycle, including manufacturing, transportation, use, and disposal. CFP calculated for control panel models equipped with OMRON products, according to May 2023 OMRON investigation.

In recent years, global warming and major disasters caused by increasing GHG*3 emissions have become social problems. To enable a sustainable society, corporations are working to reduce GHG emissions across their supply chains. In the manufacturing industry, decarbonization of the product manufacturing process is an urgent issue. Of the many approaches the industry is exploring, decarbonizing control panels, which are used in large numbers in the production line, is becoming increasingly higher priority. In the automobile industry, for example, dozens to hundreds of control panels are used in a single production line; reducing their power consumption and carbon emissions, therefore, is expected to have a significant outcome.

Through the implementation of the Green Concept, OMRON aims to reduce the CFP of its products in half by FY2025 by developing resource- and power-saving technologies, visualizing environmental impact data, and developing technologies for low-carbon materials.

- пј‘. Reducing the environmental impact of control device products by providing power-saving and compact design of configuration.

By applying its unique design technologies for the power-saving or for the down-size, OMRON can give more than 20 types of control devices to mitigate the environmental impact on all process of control panel used for the manufacturing machine. Then the continuous efforts are going on to offer the products that can achieve both, less resource and industry-leading power saving, especially the power supply product which consumes more power is spotlighted. In June 2023, OMRON launched S8VK-WA 2 kW, the world’s smallest-class power supply armed with the highest efficiency in the industry*4 along with the specifications coming from the global demand. Through such products, OMRON will support to save power and resources on the manufacturing site.

S8VK-WA(2kW type)

S8VK-WA(2kW type)

Product features

By applying OMRON’s unique technologies for boosting efficiency, the S8VK-WA, Switch Mode Power Supply, allows 60% less power, 60% less weight, and 50% less configuration than the previous products.*5 -

2пјЋFacilitating carbon reduction in control panels by providing environmental impact data based on

product specifications

To enable low carbon control panels, OMRON will provide environmental impact data on its broad range of related products. This will make OMRON define as the leading company in the industrial area and it is allowing the customers to build greener manufacturing sites, who mind environmental impact for control panel design. To assist these customers, OMRON plans to publish the information to evaluate the environmental impact on its website -

3пјЋDeveloping technologies for applying bioplastics

OMRON will accelerate its efforts to develop technologies for applying bioplastics to provide products with greener chassis which use these plastics. The company’s future goal is to use bioplastics across a broad range of its products so that carbon emissions can be reduced on an individual product basis.

OMRON has resolved labor shortage and other social issues on the manufacturing site by saving the man-hour and the space in control panel construction through “Value Design for Panel,” the common philosophy underlying the specifications of its in-panel products. Now, with the addition of the Green Concept, the company will work toward sustainable manufacturing as well by helping achieve decarbonization on the production site.

в– Main power-saving products

| Switch Mode Power Supplies | Temperature Controllers | Timers | Motor Protective Relays | |

|---|---|---|---|---|

| S8VK-S | E5CC | H3DT | K8DT | |

|

|

|

|

|

| Power consumption reduction rate (compared to previous OMRON products *6) | Approx. 44% reduction |

Approx. 13% reduction |

Approx. 78% reduction |

Approx. 39% reduction |

в– Main lightweight products

| Switch Mode Power Supplies | Ultra-Compact Interface Wiring System | I/O Relay Terminals | Motor Protective Relays | |

|---|---|---|---|---|

| S8VK-S | XW2K | G70V | K8DT | |

|

|

|

|

|

| Weight reduction rate (compared to previous OMRON products) | Approx. 41% reduction |

Approx. 27% reduction |

Approx. 44% reduction |

Approx. 31% reduction |

- пјЉ1гЂЂMajor manufacturers that develop and manufacture, in-house, factory automation devices for control panels, and sell these devices worldwide

- пјЉ2гЂЂQuantitatively calculated by converting environmental load into carbon dioxide emissions throughout the life cycle of a product (item or service), from material procurement to disposal and recycling

- пјЉ3гЂЂGreenhouse gases, including carbon dioxide

- пјЉ4гЂЂAccording to May 2023 OMRON investigation

- *5 Compared to OMRON’s S8FS-G (600 W × 3 units)

- пјЉ6гЂЂ Compared to main FY2016 products

About OMRON Corporation

OMRON Corporation is a leading automation company with its core competencies in Sensing & Control + Think technology, and is engaged in a wide range of businesses including industrial automation, healthcare, social systems, and device & module solutions. Established in 1933, OMRON has about 30,000 employees worldwide, working to provide products and services in around 120 countries and regions. For more information, please visit https://www.omron.com/global/en/

- Media Contact

- OMRON Corporation

Brand Communications Department

Marketing Communications Group

Tel: +81-75-344-7175 - Contact about our business / product

- OMRON Corporation

Component Division, Product Business Division HQ,

Industrial Automation Company

Tel: +81-75-344-7231