Adding an "Eye" of Canon to the Peripheral Devices of the Collaborative Robot

- Realization of a Flexible Manufacturing Site through Coordination of Devices -

- December 21, 2021

OMRON Corporation (HQ: Shimogyo-Ku, Kyoto; President and CEO: Yoshihito Yamada) announced today that it will add Vision Edition-T image processing software from Canon Inc. to its "Plug & Play" peripheral devices that can be used easily with TM Series of collaborative robots in the begging of January. By adding a new "eye" to the collaborative robot through the combination of network cameras and software, OMRON will expand the automation solutions for inspection processes at manufacturing sites, thereby contributing to the realization of flexible manufacturing site where humans and machines collaborate.

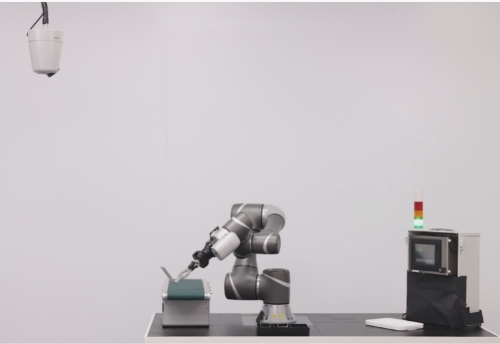

„ÄźA network camera and a collaborative robot working together for inspection using the "Vision Edition-T" image processing software.„ÄĎ

In addition to the traditional issues such as the shortage of manpower, the need for automation using collaborative robots*2 is rapidly increasing at manufacturing sites as a countermeasure against the COVID-19 infection. On the other hand, the field of view of the built-in camera on the collaborative robot is limited, and in the inspection process, it has to rely on visual inspection by humans or multiple external cameras have to be installed for each inspection point. These additional man-hours and costs have been a barrier to the installation of automation for inspection processes.

Since 2018, OMRON has been certifying peripheral devices that can be easily installed and configured on collaborative robots as "Plug & Play" devices in order to further accelerate the resolution of customer issues based on the unique concept of " innovative-Automation" This time, Vision Edition-T image processing software from Canon, which can process images of a wide range captured using network camera functions*3, has been added to "Plug & Play". By working with the built-in camera of OMRON's collaborative robots, an automation solution that will more flexibly to changeover in the types of products and in the tasks can be realized. In addition, built-in camera, which is one of OMRON's collaborative robots strengths, enables the collaborative robot to automatically compensate for misalignment with the work location, making it possible to quickly and easily start up the collaborative robot in various work cells and make the collaborative robot according to the production plan.

OMRON will continue to expand its collaborative robot automation solutions to solve customers' challenges and contribute to the realization of flexible manufacturing sites where people and robots work in harmony.

Case studies of the combination of OMRON's collaborative robot and Canon's Vision Edition-T image processing software

‚óŹ Inspection

While the collaborative robot is working, the network camera can inspect products in parallel, and it enables change over for the type of products and the inspection points easier and quicker.

‚óŹ Machine tending

When loading/unloading workpieces into/out of a machine tool by a collaborative robot, the network camera recognizes the progress status of the processing machine, making automation easy.

Features of OMRON's collaborative robots

‚óŹ Built-in high-resolution camera to "see and recognize" for work

A 5M-pixel built-in camera with a wide range of field of view and high resolution. The camera has functions: reading 2D codes such as barcodes, QR codes, and DataMatrix codes; color identification; OCR. And can be used in various processes such as inspection, measurement, sorting, and visual alignment.

‚óŹ The built-in camera reduces the start-up time for operations using cameras

The coordinates of the built-in camera have been calibrated in advance to match the robot's coordinates. This feature of the "TM Landmark" greatly reduces the time and effort required for "calibration" when relocating the robot in the field.

- *1. Network camera: A camera that can be connected to the Internet. The camera itself has its own IP address and is also called an IP camera. The camera can be connected to a computer connected to the same network to receive and control camera images. Network cameras compatible with Canon's Vision Edition-T image processing software are only available from Canon or Axis.

- *2. Collaborative robot: People and robots can work safely next to each other without safety fences, and robots can flexibly handle multiple tasks.

- *3. FeaturesÔľöPan, tilt, zoom and autofocus functions

About ‚ÄúPlug & Play‚ÄĚ

"Plug & Play" are peripheral devices can be used with our TM series collaborative robots. It enables easy installation, configuration, and easy programing to use peripheral devices. OMRON will expand variety of our "Plug & Play" devices.

About innovative-Automation

Recently, OMRON has developed a manufacturing innovation concept, called "innovative-Automation" With this concept, OMRON is currently committed to bringing innovation to manufacturing sites through three key innovations, or three "i's." Through these innovations in the area of automation, OMRON aims to enable significant productivity improvements in manufacturing sites in order to achieve high-value-added manufacturing. With the first "i," "integrated" (control evolution), OMRON will seek to advance automated control technology so that virtually any operator, even inexperienced operators, can effortlessly perform work that previously required the expert skills of experienced workers. With the second "i," "intelligent" (development of intelligence by ICT), OMRON seeks to create constantly evolving equipment and production lines. By adopting a wide range of control devices and artificial intelligence (AI), machines can learn through experience and maintain themselves in optimal condition. For the third "i," "interactive" (new harmonization between people and machines), OMRON pursues the development of a new harmonious relationship between human operators and machines; as they work together in the same workspace, machines will be able to assist human operators by recognizing human thoughts and behavior in a way that only OMRON, a specialist control equipment manufacturer who knows production floors inside and out, can realize.

About OMRON Corporation

OMRON Corporation is a global leader in the field of automation based on its core technology of "Sensing & Control + Think". OMRON's business fields cover a broad spectrum, ranging from industrial automation and electronic components to social systems, healthcare, and environmental solutions. Established in 1933, OMRON has about 30,000 employees worldwide, working to provide products and services in around 120 countries and regions. For more information, visit OMRON's website:https://www.omron.com/global/en/

- Inquiries from the press regarding this matter

- Brand Communications Department

OMRON Corporation

TEL: +81-75-344-7175 - Business Inquiries/General Customer Inquiries

- OMRON Robotics and Safety Technologies, Inc.

- Email: ORT-Marketing@omron.com