OMRON Launches K7TM Condition Monitoring Device that Realizes Preventive Maintenance of Heaters Through Digitalization of Degradation Trend

- Expansion of Solutions Contributing to the Realization of a Carbon-Free Society -

- December 9, 2021

OMRON Corporation (HQ: Shimogyo-ku, Kyoto; President and CEO: Yoshihito Yamada) announced today that it will launch globally on April 1, 2022 K7TM, a state-monitoring device that can visualize the deterioration tendencies of heater equipment used in the manufacturing processes of Automobile and Semiconductors without skill and contribute to the realization of predictive maintenance. By expanding the range of applications that predict equipment malfunctions, customers can reduce the losses that occur in the production process and contribute to minimizing the energy loss of heaters, which consume a large amount of electricity, thereby contributing to the realization of a decarbonization society.

[Monitoring the heater in the furnace with the heater condition monitoring device "K7TM" (left)]

At the manufacturing site, the issues involved unexpected downtime due to sudden equipment failure, loss of disposal of parts, and the urgent response of maintenance personnel, which had a major impact on the productivity of the entire plant. Since December 2017, OMRON has provided a "Condition Monitoring Device" series that combines its strengths of sensing technology with abnormal detection algorithms to enable monitoring of abnormal conditions in facilities. Until now, we have contributed to the innovation of maintenance that can be completed at the manufacturing site by monitoring motor abnormalities and monitoring abnormal temperatures in control panels, and by developing device that can be easily attached to existing equipment at the site.

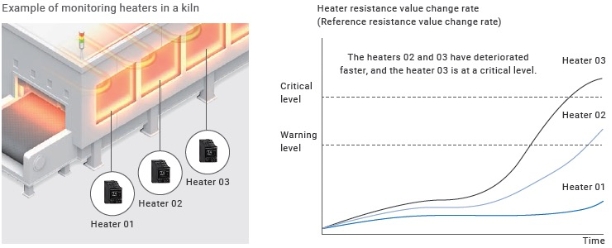

K7TM enables automatic measurement of the appropriate resistance value*1 of the heater while the facility is in operation, enabling us to determine the tendency of the heater to deteriorate numerically. This minimizes production fallout associated with regular heater maintenance and significant thermal energy and start-up times during restart. In cooperation with our product lineup*2, customers will realize maintenance activities at appropriate timing according to the heater status by accumulating rate-of-change data of resistance values for each heater. In addition, since K7TM can constantly measure the electric power of each heater, the combination of the data such as temperature enables us to obtain slight signs of abnormal conditions in the facility, and to contribute to maintaining the quality of the product by producing the product in the optimum condition. In addition, because it can be easily installed in existing equipment, it minimizes the loss caused by sudden failure of the heater and contributes to the realization of a carbon-free society by improving the efficiency of production energy.

OMRON set forth a strategic concept called "innovative-Automation" consisting of three innovations or "i's"--"integrated" (control evolution), "intelligent" (development of intelligence by ICT), and "interactive" (new harmonization between people and machines). By continuing to expand the line-up of Condition Monitoring Device, we will continue to work with our customers to accelerate the development of "intelligent" manufacturing sites, which is the key to realizing "innovative-Automation", and dramatically improve productivity and quality at manufacturing sites and creating a sustainable society.

‚Ė†Main Features of the K7TM series

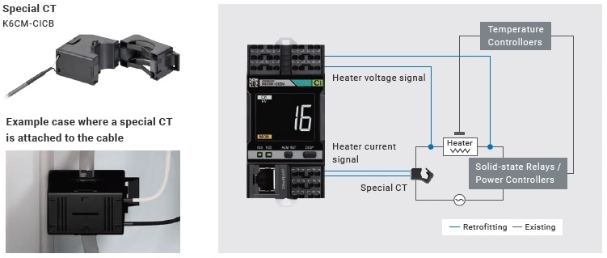

‚φ Easy to retrofit onto existing equipment

It is also easy to attach to existing facilities on the site. The voltage of the heater and the clamp type current sensor enable monitoring of the deterioration tendency of the heater simply by measuring the current value of the heater.

‚Ď° Measure the resistance of the heater automatically during equipment operation to determine the deterioration tendency of the heater

The resistance value of the heater is automatically measured without being affected by temperature control, and the rate of change is calculated. In addition, K7TM adopts a method to minimizes the effect of heater temperature characteristics, and it is possible to determine the deterioration tendency of each heater with higher accuracy.

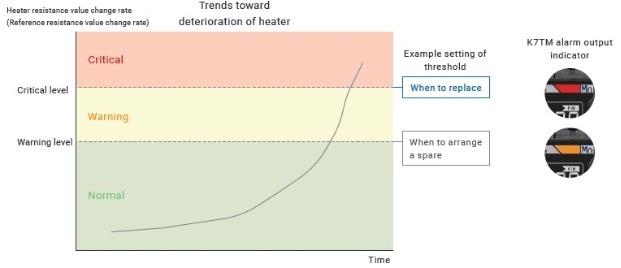

‚ĎĘ Realizing maintenance does not depend on skilled people

The deterioration state of the heater is numerically converted to the rate of change of the heater resistance value, and the threshold value can be set with the rate of change of the heater resistance value for optimal replacement timing determination. It enables maintenance activities at the optimal timing based on data, which is not dependent on skilled people or experiences.

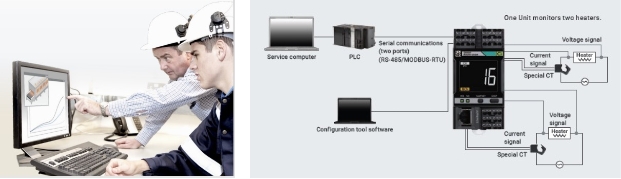

‚Ď£ Collecting measurement data remotely using network connections

In addition to on-site condition monitoring using the main unit display, network connections enable status monitoring not only on-site but also remotely while in the office.

‚ϧ Contributing to quality maintenance and carbon neutrality through visualization of heater conditions

In addition to the temperature of conventional heater equipment, the status of heater equipment is monitored constantly, and the quality status of equipment is visualized. In addition, by allowing the heater to be replaced at the appropriate timing according to the heater condition, the energy consumed when the facility is restarted is made highly efficient, which also contributes to the reduction of CO2 emissions.

*1 Resistance value: If the heater is used for a long time, oxidation will advance and the heater wire will become thinner, resulting in disconnection of the heater. As a result, the resistance of the heater increases. Disconnection of the heater has a great impact on the productivity of the equipment.

*2 Our product lineup: Machine Automation Controllers, Programmable Terminals, etc.

About innovative-Automation

Recently, OMRON has developed a manufacturing innovation concept, called "innovative-Automation" With this concept, OMRON is currently committed to bringing innovation to manufacturing sites through three key innovations, or three "i's." Through these innovations in the area of automation, OMRON aims to enable significant productivity improvements in manufacturing sites in order to achieve high-value-added manufacturing. With the first "i," "integrated" (control evolution), OMRON will seek to advance automated control technology so that virtually any operator, even inexperienced operators, can effortlessly perform work that previously required the expert skills of experienced workers. With the second "i," "intelligent" (development of intelligence by ICT), OMRON seeks to create constantly evolving equipment and production lines. By adopting a wide range of control devices and artificial intelligence (AI), machines can learn through experience and maintain themselves in optimal condition. For the third "i," "interactive" (new harmonization between people and machines), OMRON pursues the development of a new harmonious relationship between human operators and machines; as they work together in the same workspace, machines will be able to assist human operators by recognizing human thoughts and behavior in a way that only OMRON, a specialist control equipment manufacturer who knows production floors inside and out, can realize.

About OMRON Corporation

OMRON Corporation is a global leader in the field of automation based on its core technology of "Sensing & Control + Think". OMRON's business fields cover a broad spectrum, ranging from industrial automation and electronic components to social systems, healthcare, and environmental solutions. Established in 1933, OMRON has about 30,000 employees worldwide, working to provide products and services in around 120 countries and regions. For more information, visit OMRON's website:https://www.omron.com/global/en/

- Inquiries from the press regarding this matter

- Brand Communication Department,

OMRON Corporation

TEL: +81-75-344-7175 - Business Inquiries/General Customer Inquiries

- Component Division, Product Business Division HQ,

Industrial Automation Company,

OMRON Corporation

Inquiry:PreMaintenanceSolutions-COMJP@omron.com