- Highly Evaluating OMRON Ayabe Plant’s Energy Efficiency Practice -

OMRON Corporation (Head Office: Shimogyo-ku, Kyoto; President and CEO: Yoshihito Yamada) announced today that its "ECO activities to actualize visualization (energy audit) and optimization of energy at its plant" has been selected for the Energy Efficiency Best Practices for the Industry Sector of the Second Round of the International List, which is published by the Top Ten Energy Efficiency Best Practices and Best Available Technologies Task Group (TOP TENs) of the International Partnership for Energy Efficiency Cooperation (IPEEC*1) for sharing outstanding energy efficiency practices and technologies.

OMRON is making energy conservation efforts under the banner of "OMRON Carbon Zero*2," which is designed to reduce our greenhouse gas emissions to zero by 2050. The initiative at the Ayabe Plant is to actualize "visualization" (energy audit) and "optimization" of energy consumption through the effective use of OMRON's wealth of energy-saving equipment and proprietary "Environmental Andon System*3," which visualizes the status of electric power usage. Having started this initiative in 2010, by fiscal 2018 the aforementioned plant was able to reduce electricity consumption by more than 20%. More than 200 companies have since introduced the "Environmental Andon System" in an effort to reduce energy consumption at their production sites.

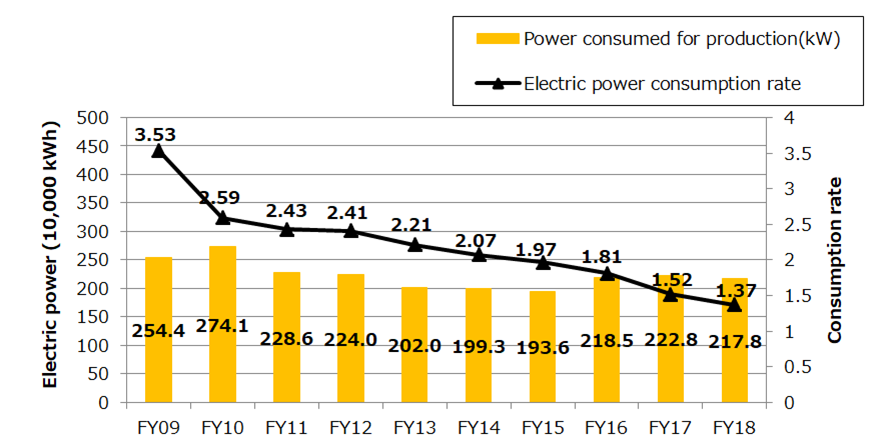

Fig. 1: Power consumption and electric power consumption rate at the OMRON Ayabe Plant

Fig. 1: Power consumption and electric power consumption rate at the OMRON Ayabe PlantTable 1: Reductions through "visualization" (energy audit) and "optimization" at the OMRON Ayabe Plant

| FY2010 results | FY2018 results | vs. FY2010 | |

|---|---|---|---|

| Electric power consumption | 2,741,000 kWh | 2,178,000 kWh | -20.5ÔľÖ |

| Electric power consumption rate*2 | -47.1% (in amount of sales) |

||

| Savings from energy conservation | JPY25.32M between FY2011 and FY2018 | ||

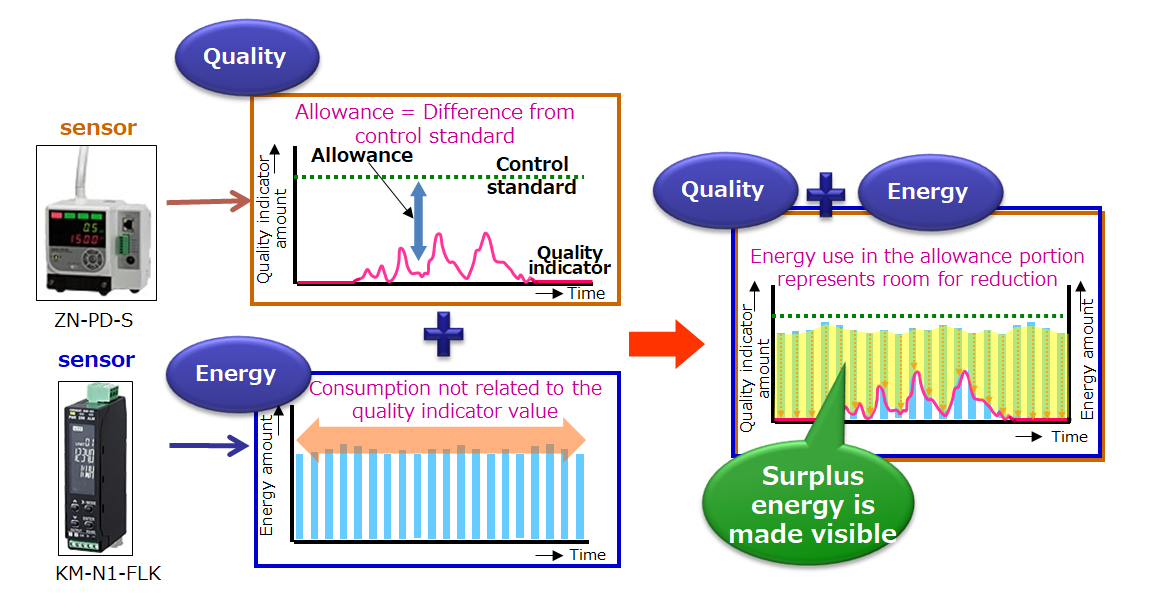

A drawback of the conventional energy amount "visualization" process was that it showed the total amount of energy used without indicating where energy was wasted or where there was room for reduction. At the Ayabe Plant, they use a variety of sensing equipment to collect data, connect energy usage with "targets" and the "present state" of quality and productivity (something that takes precedence over everything on the production floors), and centrally monitor them with the "Environmental Andon System" in real time, thus making it possible to determine where reductions could be made ("energy audit"). For example, they monitor the amount of particles*4 in the clean room using environmental sensors to visualize any difference between the standard and the present state as a quality indicator. By connecting this with the amount of energy used for analysis, they are now able to quantify a room for reducing energy consumption and determine the appropriate amount of energy use. They can then go on to use the resultant data to have clean units and other equipment control themselves automatically in accordance with the amount of particles in the room, thus "optimizing" energy efficiency by achieving a balance between "energy conservation of equipment" and "quality and productivity." Allowing everyone at the plant to keep themselves updated on their environmental efforts, the "Environmental Andon System" serves as a communication tool to get everyone involved in energy conservation projects, which yielded a total of 72*5 cases of energy conservation/environmental improvement.

Fig. 2 Determining "allowance" to trim energy consumption

Fig. 2 Determining "allowance" to trim energy consumptionThe "Environmental Andon System" was first introduced to the commercial market in 2013 and its successor model with enhanced functions was made available in Japan in 2018. The" i-BELT Viewer", as it is called, is a tool for visualizing various types of data collected from production floors, in addition to energy and quality. Enabling analyses by connecting the plant's management indicators and field data, the "i-BELT Viewer" sheds light on the true causes of challenges facing the plant, thus facilitating both management and field workers to unite as one to solve them.

Upholding the principle of contributing to a better society through our business, OMRON seeks to contribute to the realization of a sustainable society. We will continue to involve our customers in our endeavor to combine energy conservation and optimal manufacturing to achieve the ultimate goal of preserving the global environment.

*1. IPEEC: IPEEC is a partnership of nations founded in 2009 by the Group of 8 (G8) to promote collaboration on energy efficiency. Its membership now includes 17 of the Group of 20 (G20) economies, and facilitates candid discussions for exchanging ideas and experiences and helping countries undertake joint projects to develop and implement energy efficiency policies and measures at a global scale.

*2. OMRON Carbon Zero: OMRON's environmental target that aims for zero greenhouse gas emissions by 2050. Established in 2018 to contribute to a better society. For details, please visit https://www.omron.com/media/press/2018/07/c0727.html.

*3. Environmental Andon System: An environmentally friendly manufacturing support tool implemented with energy conservation know-how gained at the OMRON Ayabe Plant. While maintaining/improving quality and productivity--the two most important parameters at a manufacturing site --this visualization (energy audit) tool facilitates energy conservation efforts and helps maximize the efficiency of electric power and other energy sources. The "Environmental Andon System" meets the demand from field workers, who wish to establish energy conservation activities within the Group by involving everyone in continued efforts to conserve energy, rather than letting such activities they have engaged in end up as temporal improvement activities.

*4. Particles: Grit and dust that negatively affect product quality

*5. 72 cases: As of April 2019

OMRON Corporation is a global leader in the field of automation based on its core technology of "Sensing & Control + Think". OMRON's business fields cover a broad spectrum, ranging from industrial automation and electronic components to automotive electronic components, social infrastructure systems, healthcare, and environmental solutions. Established in 1933, OMRON has over 35,000 employees worldwide, working to provide products and services in 117 countries. In the field of industrial automation, OMRON supports manufacturing innovation by providing advanced automation technologies and products, as well as through extensive customer support, in order to help create a better society. For more information, visit OMRON's website at: https://www.omron.com/.