We are Shaping the Future! Showcasing Success Stories as We Innovate for a Sustainable Tomorrow

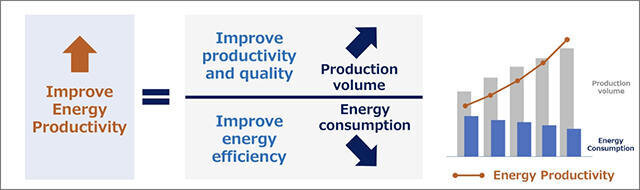

At a factory in western Japan, technology pioneer OMRON is deploying advanced data analytics to drive new models of energy productivity--the ratio of economic output to energy consumption--that hold surprising answers in the mission to achieve a net-zero world.

Reducing a factory's energy use while driving business growth might seem to be opposing business objectives. In fact, research shows that energy efficiency can deliver more than 40% of the reduction in energy-related emissions by 2040, even as it improves the bottom line through cost savings--a virtuous circle of enterprise value and green transformation. To achieve both carbon neutrality and business growth, OMRON has committed to doubling its energy productivity, declaring a goal of 200% of sales per Gigawatt Hour (Gwh) by 2040, compared to 2016 levels.

At OMRON's Matsusaka healthcare plant, a multidisciplinary team from the company's industrial automation and healthcare divisions came together to unlock a next-generation energy productivity solution through data-driven automation that visualizes production volume, quality, and energy consumption and ascertains the potential for energy reduction. Through collaborative deployment of its i-BELT data management platform--an advanced Internet of Things (IoT)-enabled solution that streamlines the integrated management of diverse data-- the partnership achieved energy productivity breakthroughs that can now be spread beyond the OMRON family.

Robb Black, president, CEO & COO at OMRON Automation Americas

Robb Black, president, CEO & COO at OMRON Automation AmericasIt's a leading example of the firm's ethos of "co-creation" of solutions for humanity that goes to the heart of OMRON's mission to contribute to a better society through innovation--and is today driven at a global level with client partners in industries ranging from automaking to logistics. Now OMRON is merging the partnership vision with its commitment to energy productivity by becoming the first Japanese manufacturer to join the EP100--a global coalition for energy efficiency. The initiative led by the non-profit Climate Group brings together more than 120 energy smart businesses committed to partnership on energy productivity.

"I am pleased to announce OMRON's accession to the EP100, a transformative framework in which we believe we can make energy efficiency impact through collaboration," says Robb Black, president, CEO & COO at OMRON Automation Americas. "What co-creation means in OMRON's own business is working with customers to understand where their energy is being used today and how to reduce it overall. By joining the EP100, we now gain a forum for taking the vision to a higher level by exchanging learnings about energy productivity with major global corporations. It's a giant collaborative sharing organization--that's how I see the EP100."

ŃĆĆ

Overcoming challenges in energy productivity at OMRON's Matsusaka plant has been cause for celebration throughout the company--as well as an opportunity to share learnings among internal stakeholders, global clients and within the EP100 framework.

The collaborative achievements came to vibrant life at this year's presentations of The OMRON Global Awards (TOGA)--a global program that honors teams and individuals who have driven social innovation that embodies OMRON principles in action. This year, Ryuichiro Takaichi, an engineer in OMRON's Industrial Automation Business (IAB), spoke about how diverse teams came together at the Matsusaka plant to achieve energy productivity, while unlocking business value through the power of automation.

Ryuichiro Takaichi, an engineer in OMRON's Industrial Automation Business (IAB)

Ryuichiro Takaichi, an engineer in OMRON's Industrial Automation Business (IAB)"Personally, I was motivated by three main factors: a sense of urgency about decarbonization and the future of manufacturing, deep bonds with colleagues across divisions who shared my goals for social good, and the culture of social innovation at the OMRON healthcare division," says Mr. Takaichi. "Together, in a spirit of friendship, we came to the conclusion that the problem that needed to be solved was 'both decarbonization and growth'--and that the solution was energy productivity. The question we all rallied around was, 'How do we contribute to society?' Through that guiding principle we were able to gain the support and empathy of those around us--and together drive innovative solutions in our collective goal to double energy productivity using i-BELT."

The mission Mr. Takaichi describes has been a journey in the making for more than a decade. Since 2010, OMRON IAB has been working to balance quality and productivity improvements with environmental conservation at its plant in Ayabe City, Kyoto, and other in-house factories. In doing so, OMRON has pioneered energy productivity models that today are seen as increasingly vital to overcoming climate challenges.

"We are proud of our contribution to the manufacturing industry and society through energy productivity improvement technologies and know-how that we can deliver--both as products and platform services--to our own production sites and those of our customers," says Tim Hill, Manager, Investor Relations, OMRON Management Center of America Inc.

"By joining EP100, we now gain a forum for taking the vision to a higher level

by exchanging learnings about energy productivity with major global corporations.

It's a giant collaborative sharing organization--that's how I see EP100."

-- Robb Black, president, CEO & COO at OMRON Automation Americas

ŃĆĆ

Specifically, OMRON's IAB technology for visualizing energy consumption on manufacturing lines will be used to analyze energy data from manufacturing lines at the Matsusaka plant, a domestic production site for the Healthcare Division, in order to improve energy productivity.

The technological driver of this mission has been i-BELT, which had never before been utilized to bring about improvement on manufacturing floors. Imaginative deployment of the system enabled the ability to integrate energy data and productivity data to produce an indicator for energy productivity--which can be used to drive initiatives to achieve carbon neutrality.

Mr. Naoki Sone, general manager at the Matsusaka plant, says the joint project has been inspiring further cross-departmental initiatives in OMRON's production, development and sales divisions, thus expanding the scope beyond one production site to include logistics and the supply chain--driving a virtuous circle of partnership and innovation.

Mr. Naoki Sone, general manager at the Matsusaka plant

Mr. Naoki Sone, general manager at the Matsusaka plant"At the Matsusaka plant, management and even young leaders from related departments participated in the project, which allowed us to drive ever more diverse and challenging initiatives," says Mr. Sone. "There was a real desire to spread it widely and deeply not only within the healthcare business, but throughout the OMRON Group and to other manufacturing companies around the world. By doing so, we can drive an exponential effect in our ability to improve energy productivity."

ŃĆĆ

Mr. Hideaki Takiguchi, IAB general manager, OMRON, captures the achievement by highlighting a key OMRON principle of a circle of empathy that extends far beyond the production site to include stakeholders throughout the company's innovation ecosystem, including customers and suppliers.

"Within the company, we share actual examples of our successes, the reactions of customers to the front-line salespeople who have worked with us, and use an internal communication site to share information," says Mr. Takiguchi, "thereby expanding the circle of understanding and empathy."

It's co-creation in action that grows from the gemba--a revered Japanese word for the factory floor, where value comes to life--to flourish throughout the partnership ecosystem, and today promises to achieve transformative global scale through the EP100 alliance.

"This is all about sharing the learnings. I think that's going to be the goal as we collectively face an existential threat from climate change," says Mr. Black. "The opportunity now with the EP100 is to bring global organizations together to uncover and resolve problems of the future. As OMRON develops innovative ideas and solutions on our own, we can then co-create with customers, and share this knowledge with our partners in the EP100."