OMRON to Launch Industry's Smallest* Battery Connector with 2mm Pitch and 2.6mm Depth - Significantly Reduces Onboard Footprint -

FOR IMMEDIATE RELEASEDecember 6, 2012

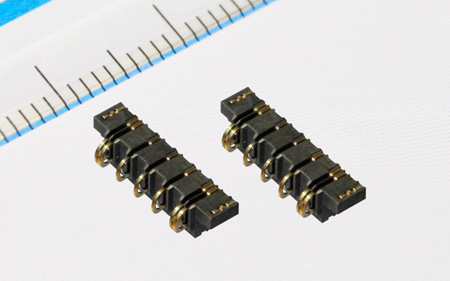

Kyoto, Japan -- OMRON Corporation (TOKYO: 6645, ADR: OMRNY) today announced the planned launch of its new XD2B battery connector in mid-December 2012. With a pitch of 2mm and a depth of 2.6mm, this new battery connecter is the smallest of its kind currently available in the industry.* The ultracompact XD2B battery connector is compatible with batteries for smartphones and other mobile devices.

* As of December 6, 2012, according to OMRON survey

Development Background

As mobile devices such as smartphones incorporate increasingly higher functionality and slimmer designs, it is necessary to reduce the size of components embedded in these devices without compromising reliability. Connector contacts are usually formed by a pressing process, but currently available pressing technology has several drawbacks. For instance, with the conventional technology it is difficult to make the width of formed products smaller than the thickness of the original sheet to be pressed, and there are limitations to how far the bending radius of metal can be reduced. These drawbacks make it difficult to satisfy customer demand for greater miniaturization and higher contact reliability.

OMRON has circumvented these problems by developing a new electroforming technology based on further advancement of its microfabrication and materials technologies. This advancement has led to the development of a battery connector with a 2mm pitch and a 2.6mm depth, using subminiature contacts that are impossible to form with conventional press technology.

Features

- The industry's smallest pitch and depth

The XD2B's significantly reduced PCB footprint contributes to further miniaturization of devices and larger battery sizes. - High contact reliability

The XD2B's contact is substantially stronger than conventional pressed materials. Its spring-contact configuration fits tightly to the battery contact pad improving contact force, and providing greater resistance against momentary power outages caused by drop impacts.

Price

Open

Sales Target

1,000,000 units/month

Factory in Charge

Yasu Plant, OMRON Corporation

Ratings and Specifications

| Rated current/voltage | 2A DC, 5V DC |

|---|---|

| Contact resistance | 35 mΩ max. (2-pin contact, at 20 mV DC max., 100 mA max.) |

| Battery insertion/removal tolerance | 5,000 times |

| Ambient operating temperature | -30° to +85°C (with no icing or condensation) |

Material

| Housing | LCP resin (UL94V-0)/black |

|---|---|

| Contacts | Nickel alloy/nickel substrate Gold-plated contact section/mounting section |

| Hold-down clips | Brass/nickel substrate Gold-plated mounting section |

Future Plans

OMRON plans to expand the range of applications of its electroforming technology to include inspection sockets for semiconductors and other high-precision micromachined components.

OMRON's Electroforming Technology

Electroforming is a metal forming process that forms ultra-thin metal components through the electroplating process. The components are produced by developing a layer of metal onto a base form (master). Once the plated layer has been built up to the desired thickness, this newly formed part is stripped off the master substrate. Electroforming enables high-precision production of extremely small, thin and fine parts. OMRON also produces dies using microfabrication technology to meet more exacting needs for shapes and sizes, thus enabling transfer of a pattern with submicron-scale (0.0001mm) accuracy.

Visit the website below for more information about OMRON's micro contacts and electroforming technology: https://www.omron.com/ecb/products/cn/special/index.html

About OMRON

Headquartered in Kyoto, Japan, OMRON Corporation is a global leader in the field of automation. Established in 1933, and headed by President Yoshihito Yamada, OMRON has more than 37,000 employees in over 35 countries working to provide products and services to customers in a variety of fields including industrial automation, electronic components, social systems, and healthcare. The company has five regional head offices in Kyoto (Japan), Singapore (Asia Pacific), Shanghai (Greater China), Amsterdam (Europe, Africa, and the Middle East), and Chicago (the Americas). For more information, visit OMRON's website: https://www.omron.com/

- Sales Inquiries

- Jiro Koyama,

Marketing Section,

Connector Division,

OMRON Electronic and Mechanical Components Company

Email: cn_marketing@omron.co.jp

Tel.: +81-44-812-3432

- Media Inquiries

- Arlo Cook (arlo_cook@omron.co.jp)

OMRON Corporate Communications Department

Tel.: +81-3-6718-3430