"Make in India" established in India

There is an urgent need for India to strengthen the competitiveness of the manufacturing industries in order to develop into a manufacturing and export base in the world.

Chennai (Tamil Nadu), one of the leading world cities in India and a center of commerce and industry, government and culture in South India, has a concentration of manufacturing industries especially the automotive industry with a growing expectation that it will be an export base to the world.

What innovation is required to accelerate the development of the manufacturing industries in India? What role should Japanese companies play for it?

On March 15, 2016, Nikkei Business Publications, Inc. and The Overseas Human Resources and Industry Development Association (HIDA) held "Asia Monozukuri Conference" in Chennai.

More than 200 attendees including managers and executives of production departments and research and development departments from Indian companies listened intently to the lectures delivered by companies that are leading innovation in the manufacturing industries.

OMRON, along with automakers, electronic components manufacturers, and the world's leading engineering universities in India, participated.

In a factory session, Sameer Gandhi, managing director of OMRON Automation PVT Ltd. (OEP-IN), explained the importance of quality control which is the base of manufacturing and also introduced examples of the quality tracing solutions and traceability.

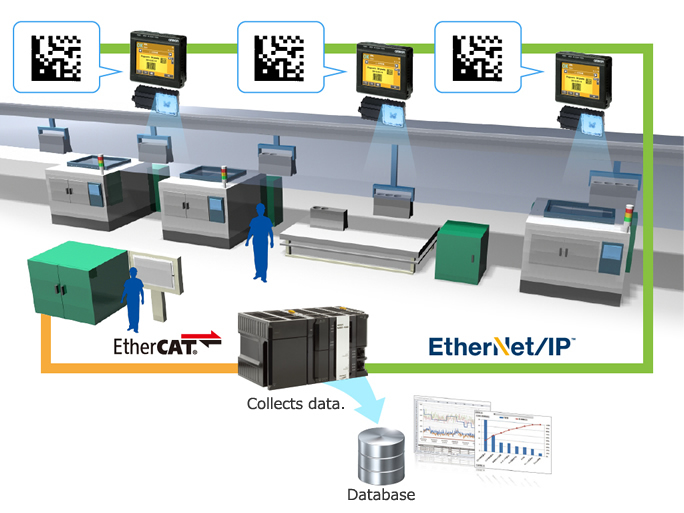

Traceability means the ability to trace the history of a product even after shipment through the clarification of the production process by recording the history of a product, parts and materials that are on the product line in the factory and the actual operational history of each product.

"Supply chains have become complicated, making it difficult to identify the cause of a problem that occurs in a manufacturing process or the market. Meanwhile, a company often suffers from a great loss caused by even a single problem. To solve these problems simultaneously, traceability is essential" said Sameer Gandhi, emphasizing the importance of traceability in manufacturing in India.

Quality control strengthened and cycle time shortened simultaneously

Increasing the number of tracing items always leads to a huge amount of data, which is problematic.

Sameer Gandhi introduced an example of the latest system of machine tools used in the automotive industry, which simplifies the complicated system and stores a huge amount of data at a faster speed without failure.

He also introduced a system that automatically inspects and records all items using an image sensor replacing check by manual inspection and entry at over 30 points as an example of an engine assembly manufacturer that uses the traceability system in the inspection process. This system not only allows automatic management of products by using serial numbers but also contributes to significantly improving productivity by 5 to 7 times.

"OMRON will continue to work to bring innovation to manufacturing in the production sites by further developing the wide range of automation technology and services as a partner in India that seeks high quality to realize "Make in India", concluded Sameer Gandhi.

© Copyright OMRON Corporation 2007 - All Rights Reserved.