PRODUCT&

SERVICE SOLUTION

We develop a wide range of control products, applications, and services designed to solve a variety of challenges faced by manufacturers, with a focus on essential management issues as well as on-site issues and problems related to production lines. We accomplish this by drawing on the latest AI, IoT, and robotic technologies and refining them with a view to enhancing their usability and delivering value to our customers.

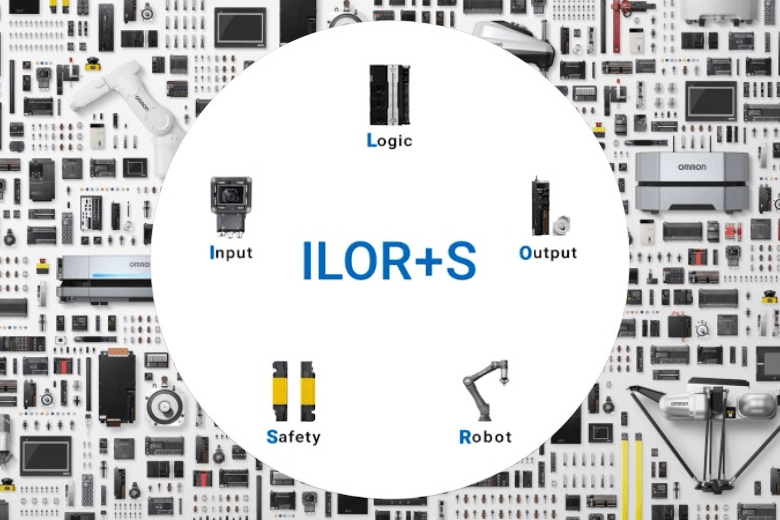

SENSORS/INDUSTRIAL AUTOMATION DEVICES

While creating many first-in-the-world and first-in-Japan innovations, we have expanded our product lineup to include input devices (such as sensors), control (logic) devices (such as programmable logic controllers), output devices (such as servomotors and servo drives), industrial robots, and safety devices. These products are collectively referred to as “ILOR+S” products, an acronym derived from the first letters of the respective functions.

OMRON’s ILOR+S products can be freely combined to match a broad range of applications and situations. In addition, we finely coordinate these products with software to provide as many as 250 control applications. This capability is a strength unique to OMRON, a solutions provider that offers a comprehensive range of ILOR+S products required for constructing industrial automation systems.

ROBOTS

Conventional robot-based automation is mainly concentrated on pick-and-place applications, which require specialized human knowledge and skills to operate the robots, meaning that only expert technicians can use them. OMRON’s aims are to increase the variety of tasks that can be handled by robots, to empower more operators to effectively use robots, and to create a manufacturing environment in which these operators can work in a comfortable and rewarding manner.

OMRON proposes control applications that match control devices and robots with each other, automating tasks that until now could only be handled by human operators. Specifically, OMRON enables completely seamless process-to-process automation, while allowing even nonexpert operators to make effective use of automation. Our goal is to realize “autonomation” or autonomous automation that unleashes human potential and creativity to the fullest extent with the aid of robots, as we seek to serve as a truly dependable partner that can help build manufacturing sites that are ideally suited for each customer.

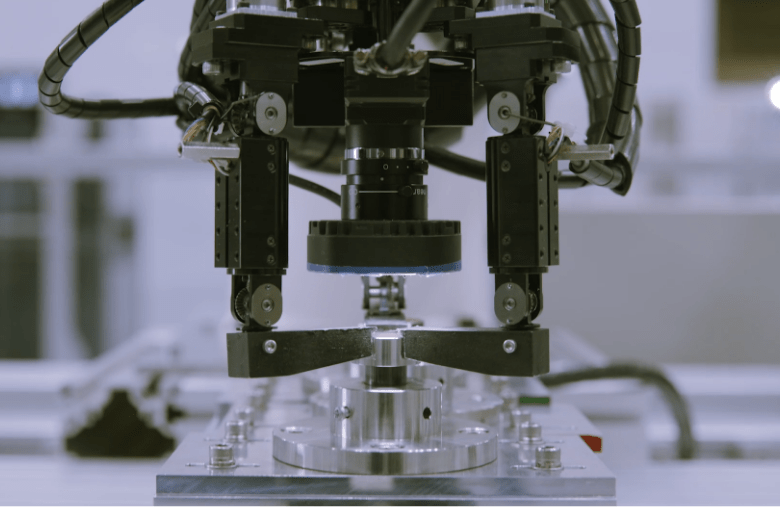

INSPECTION SYSTEMS

As market requirements become more sophisticated and diverse due to advances in technology, demands for higher quality grow increasingly severe. Moreover, the declining workforce has created an urgent need to recruit new production workers and train personnel to take over existing expertise, in addition to introducing additional equipment and making performance improvements.

OMRON also provides inspection-based productivity improvement solutions, which include eliminating missed failures and avoiding the need for excessive monitoring by using a high-precision inspection system, and minimizing the time and skills required for programming by combining quantitative inspection and AI. Furthermore, we assist in building manufacturing environments that effectively prevent defects from occurring by using accurate quality data from inspection equipment together with production data to analyze failure trends and formulate countermeasures, while also providing support for the automation of tasks that currently rely on the intuition and experience of skilled workers.

SOLUTION SERVICES

In today’s world, where consumer needs are changing in line with increasing market globalization, manufacturers are also under growing pressure to become carbon neutral. On top of this, despite advances in production technology brought about through the implementation of digital technology, they are confronted by other major challenges, such as a low birthrate and an aging population, as well as by changing values among factory workers. Under these circumstances, manufacturers must adapt to rapid changes in the manufacturing environment and overcome a variety of dilemmas in order to meet social demands that are essential for sustainable development.

OMRON is determined to address the diverse on-site issues that arise out of the need to meet social challenges. Aware of both the current state of manufacturing and the idealized manufacturing sites that our customers want to achieve, we will continue to aim at the evolution of manufacturing sites from the four perspectives of the manufacturing process, quality, equipment, and energy. To this end, we will make data an on-site common language so that management issues can be manifested in terms of data.

Global Career Development

OMRON sales representatives and field application engineers stationed in 150 locations that are spread across approximately 40 countries and regions around the world stand ready to help our customers solve all kinds of manufacturing-related issues. We are confident that this is a superb field in which you can make the most of your career.