OMRON to Release New Industrial PC Platform, Making Production Sites "Integrated" and "Intelligent"

July 27, 2016

OMRON Corporation (HQ: Shimogyo-Ku, Kyoto. CEO: Yoshihito Yamada) announced on July 27 the global release in August of its new Industrial PC Platform (hereinafter "IPC") to innovate manufacturing through IoT utilization and high-speed, high-precision automation.

The IPC is a PC architecture based platform that meets strict quality standards required for factory automation (FA) devices and can be supplied stably on a long-term basis. OMRON assists manufacturers to make production equipment smarter by utilizing IoT and big data through the IPC. At the same time, OMRON helps them boost both their equipment productivity and manufacturing quality by applying know-how on advanced fine-tuning control, which OMRON has gained through the Sysmac automation platform *1, to production lines and equipment.

The current trend to aim for innovative manufacturing by leveraging IoT, big data, and robotics at production sites is spreading. In order to collect data for preventive maintenance, a programmable logic controller (PLC) is connected with a PC for office environments which requires complex license management and is supported only for a short time. Moreover, builders of semiconductor manufacturing equipment and machine tools in-house produce dedicated boards, equipped with real-time operating systems, as main controllers. They are outsourcing development of general control functionality and concentrating resources on development of competitive core technology. These circumstances increase the global needs for PC architecture based controllers which provide environmental resistance and reliability and allow for flexible development.

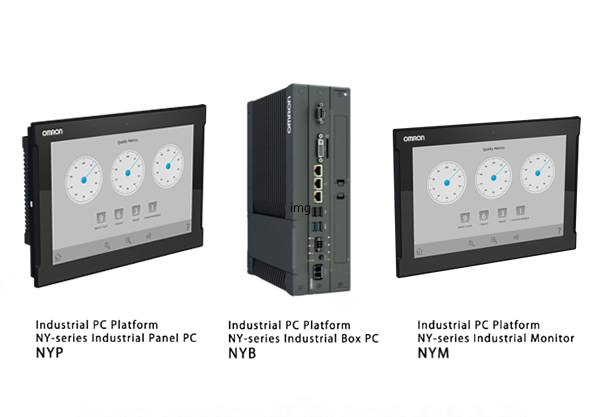

OMRON has captured these needs and developed three types of IPCs. Users can choose the best IPC from box-type PC models and all-in-one PCs with built-in monitors to suit their system configurations and applications. The IPC supports EtherCAT that is an open network used for production lines and equipment all over the world, as well as providing a development environment that allows users to customize functionalities, which was impossible with previous PLC.

Industrial PC Platform

- Industrial PC

The Industrial PC offers robustness and reliability for applications in FA environments and is suitable for use with both Windows software and programs for machine control and automation. Production data can be collected to ensure stable equipment operation. - Industrial PC: IPC Machine Controller *2

The IPC Machine Controller combines the precision and speed of the NJ/NX series of Machine Automation Controller with the versatility and range of Windows programs on single platform by using OMRON's unique hypervisor function. This achieves both production data handling and advanced fine tuning control using ILOR+S (Input, Logic, Output, Robotics + Safety). - Industrial PC: IPC RTOS Controller *3

Coming equipped with a real-time operating system *4, the IPC RTOS Controller enables both real-time control and execution of data-processing tasks.

Users can utilize OMRON's high-speed, high-precision and real-time machine control in the same programming environment based on familiar C-language (C/C++) as with dedicated boards produced in-house by semiconductor-manufacturing equipment builders.

OMRON brings innovation to manufacturing sites through automation with "integrated", "intelligent" and "interactive" concepts. The IPC is a new control platform that delivers "integrated" and "intelligent" automation to production sites and equipment around the world. OMRON is going to work on manufacturing innovation with manufacturers by developing OMRON's unique automation using a wide range of FA product lineup, including PLC and IPC, and open industrial networks such as EtherCAT.

- *1. Sysmac automation platform:

OMRON's integrated automation platform is dedicated to providing complete control and management of automation plant under one software. Programming based on global standards and global open networks allows for building the globally standardized system. At the core of this platform, the machine controller series offers synchronous control of all machine devices and advanced functionality such as motion, robotics and database connectivity. This multidisciplinary concept allows you to simplify solution architecture, reduce programming and optimize productivity. - *2. The Industrial PC IPC Machine Controller will be available soon.

- *3. Available in Japan only.

- *4. Choice of real-time operating systems: Linux and VxWorks.

Main specifications

| Product name | Industrial PC | IPC Machine Controller *5 | ||

|---|---|---|---|---|

| Appearance |  |

|

|

|

| Type | Industrial Box PC | Industrial Panel PC | Industrial Box PC | Industrial Panel PC |

| Model | NYB | NYP | NY51[] | NY53[] |

| Operating system | Windows Embedded Standard 7 - 32 bit Windows Embedded Standard 7 - 64 bit |

Windows Embedded Standard 7 - 32 bit Windows Embedded Standard 7 - 64 bit |

||

| Function module | --- | Machine Automation Control Software | ||

| Number of axes | --- | 16, 32, 64 | ||

| CPU type | Intel® Core™ i7-4700EQ Processor 4th generation CPU with Fan Unit for active cooling Intel® Core™ i5-4300U Processor 4th generation CPU with fanless cooling Intel® Celeron® 2980U Processor 4th generation CPU with fanless cooling |

Intel® Core™ i7-4700EQ Processor 4th generation CPU with Fan Unit for active cooling | ||

| RAM memory (non-ECC type) |

2 GB, 4 GB, 8 GB | 8 GB | ||

| Storage | HDD, SSD, SD memory card | HDD, SSD, SD memory card | ||

| Screen size | --- | 12.1 inches *5, 15.4 inches | --- | |

| Built-in ports |

|

|

||

| Interface option | RS-232C, DVI-D | RS-232C, DVI-D | ||

| Expansion slots | 1 PCIe slot | 1 PCIe slot | ||

*5. Coming soon

| Product name | IPC RTOS Controller *6 | |

|---|---|---|

| Appearance |  |

|

| Type | Industrial Box PC | |

| Model | NYB[][]-[][]A | NYB[][]-[][]B |

| Operating system | Wind River Linux 7 with Acontis EtherCAT Master Wind River | VxWorks 7 with Acontis EtherCAT Master |

| Function module | --- | |

| Number of axes | --- | |

| CPU type | Intel® Celeron® 2980U Processor 4th generation CPU with fanless cooling | |

| RAM memory (non-ECC type) |

8 GB | |

| Storage | HDD, SSD, SD memory card | |

| Screen size | --- | |

| Built-in ports |

|

|

| Interface option | RS-232C | |

| Expansion slots | 1 PCIe slot | |

*6. Available in Japan only.

| Product name | Industrial Monitor *7 | |

|---|---|---|

| Appearance |  |

|

| Model | NYM12 | NYM15 |

| Display device | TFT LCD | |

| Screen size | 12.1 inches | 15.4 inches |

| Resolution | Up to 1,280 x 800 pixels at 60 Hz | |

| Colors | 16,770,000 colors | |

| Connectors |

|

|

| Allowable power supply voltage range | 19.2 to 28.8 VDC | |

*7. Coming soon

- Sysmac is a trademark or registered trademark of OMRON Corporation in Japan and other countries for OMRON factory automation products.

- Windows is either a registered trademark or trademark of Microsoft Corporation in the United States and/or other countries.

- EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

- EtherNet/IP™ and DeviceNet™ are trademarks of ODVA.

- The SD and SDHC logos are trademarks of SD-3C, LLC.

- Intel, Celeron, and Intel Core are trademarks of Intel Corporation in the U.S. and/or other countries.

- Other company names and product names in this document are the trademarks or registered trademarks of their respective companies.

About OMRON Corporation

OMRON Corporation is a global leader in the field of automation based on its core technology of sensing and control. OMRON's business fields cover a broad spectrum, ranging from industrial automation and electronic components to automotive electronic components, social infrastructure systems, healthcare, and environmental solutions. Established in 1933, OMRON has over 38,000 employees worldwide, working to provide products and services in more than 110 countries and regions. In the field of industrial automation, OMRON supports manufacturing innovation by providing advanced automation technologies and products, as well as through extensive customer support, in order to help create a better society. For more information, visit OMRON's website at: https://www.omron.com/

- Contact (media):

- Corporate Communications Department

OMRON Corporation

TEL: +81-75-344-7175 - Contact (product information):

- Controller Division,

Product Business Division HQ.

Industrial Automation Company,

OMRON Corporation

TEL: +81-75-344-7173