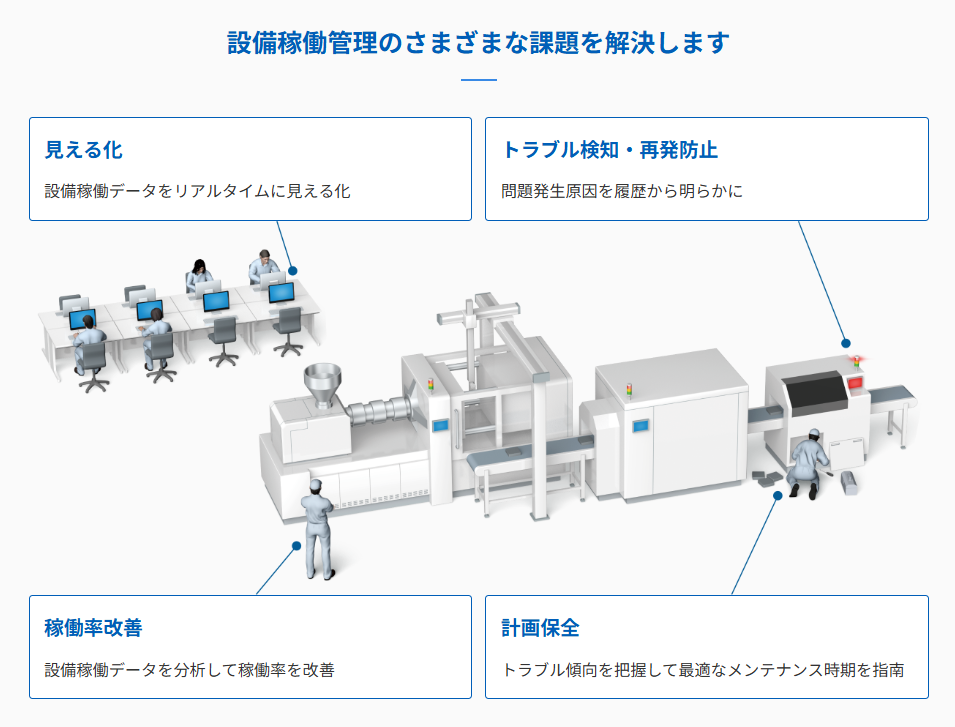

The equipment operation management system provides data that helps improve equipment utilization rates and accelerates our clients’ improvement activities

Our system can shorten the time required for improvement by collecting real-time data on equipment operating status and trouble factors as they occur. In addition, equipment management operations based on the experience and knowledge of experts can be digitized and passed on to future generations.

Our system enables remote, real-time monitoring of multiple pieces of equipment through detailed data and video. When an abnormality occurs, an alert is issued immediately, allowing a quick response. This helps reduce equipment downtime and maintain stable, continuous operation.

We collect operating data from more than 100 sensors and PLCs, and by storing and analyzing that data, enable efficient equipment management. Through data-driven post-event analysis, we thoroughly pinpoint root causes of issues; by capturing and codifying expert know-how, we preserve and transfer maintenance tasks that previously depended solely on seasoned technicians.

By combining equipment trouble data with camera footage from the production site, the system shortens the time required to analyze and address the causes of downtime. In addition, by examining the frequency and patterns of past equipment issues, it helps determine the priority of improvement actions, enabling effective corrective measures to be implemented in a shorter timeframe.

Clients are welcome to share their needs or concerns.

We analyze our clients' on-site needs and provide a concrete proposal for system implementation.

We support the installation of required equipment and system setup to ensure a smooth start of operations.

We provide ongoing operational support and improvement proposals to help clients manage their equipment more efficiently.

We install a mechanism that collects operation data directly from your equipment's PLC. Even if your equipment does not include a PLC, we can still provide support. Please feel free to contact us.

The system visualizes quantified indicators of equipment operation and trouble histories.

Optional features include event videos recorded by drive recorders, along with maintenance information that prompts actions such as parts replacement, etc.

Depending on your site conditions, implementation typically takes around 3 months from the start of development.