LightMES consolidates on-site data, enabling progress management without depending on individual workers and creating a continuous cycle of improvement.

LightMES enables smarter management of production and quality through data utilization. The system reduces dependence on manual effort, minimizes upfront costs, and allows for rapid implementation of key functions.

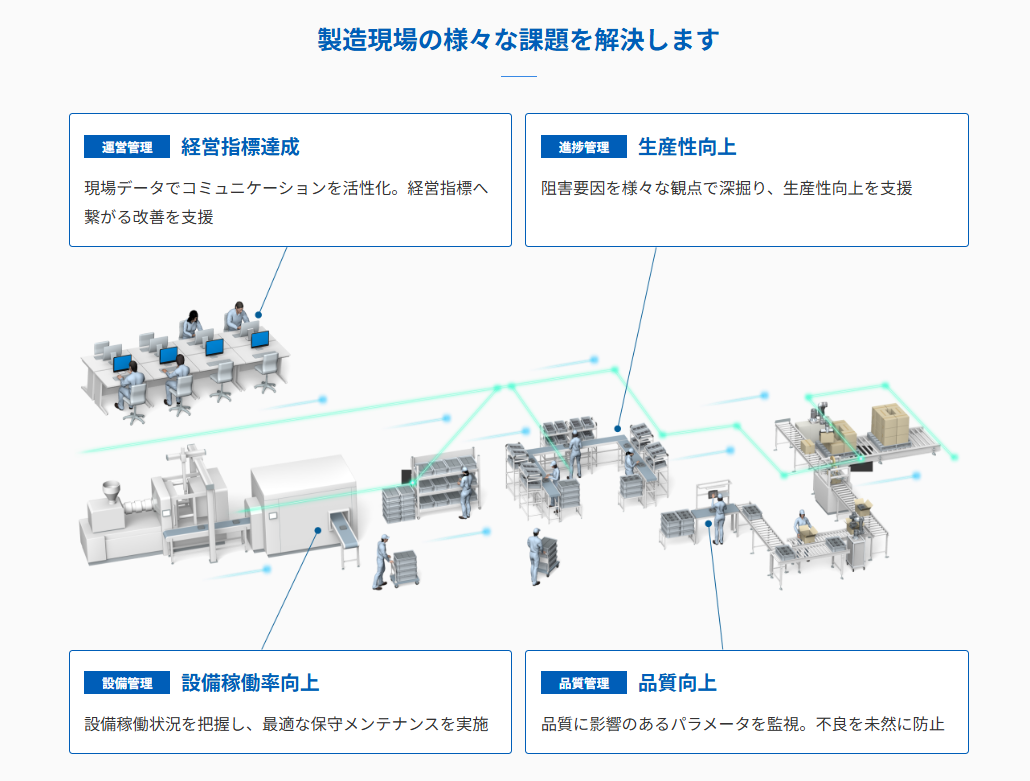

By sharing real-time production data based on line, process, and product between management and on-site teams, we can create an environment that supports data-driven decision-making, which will accelerate improvement cycles and support sustainable growth and profitability

Real-time monitoring of production time and progress by line and process enables the maximization of productivity.

Track quality indicators for each process, predicting and analyzing variations to prevent defects before they occur.

Equipment data can be collected automatically to visualize performance issues and maintain optimal operating conditions.

Data can be collected from various types of equipment, transforming it into valuable insights that contribute to proactive manufacturing site management.

Clients are welcome to share their needs or concerns.

We conduct an assessment to understand the specific challenges of your production environment.

We propose the optimal solution.

We support smooth implementation and assist with sustainable improvement activities.

LightMES visualizes key production indicators such as performance against production plans, efficiency by line or process, equipment operating status, and quality variation trends.

Depending on your site conditions, implementation typically takes around 5 months from the start of development.