OMRON Develops the World's First* 16x16 Element MEMS Non-Contact Thermal Sensor for Use in Human Presence Sensors Utilizing Wafer-Level Vacuum Packaging Technology

May 29, 2013

For reference only ( no sample)

Please direct the enquiries to the following number.

OMRON Corporation

Business Management Division HQ Sensing & Module Division.

Electronic and Mechanical Components Company

TEL:+81-75-344-7148

TOKYO, Japan -- OMRON Corporation (TSE: 6645, ADR: OMRNY) today announced that they have finished development work on the world's first infrared sensor manufactured with wafer-level vacuum packaging technology to create a 16x16 element MEMS non-contact infrared thermal sensor capable of highly precise 90-degree area detection. Shipping of test samples will commence in October 2013.

In recent years the demand for human presence sensors has been growing in tandem with the demand for energy-efficient "smart home" and "smart office" environments in which lighting, heating, etc. is automatically controlled according to where people are.

Since conventional pyroelectric human presence sensors (motion sensors) are only able to detect people when they are in motion, they are not as suitable for detecting the number of people in a certain space or their relative positions as OMRON's new thermal sensor.

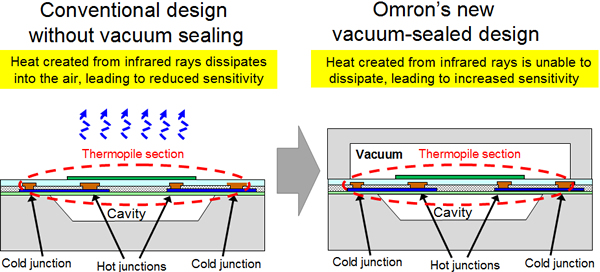

MEMS non-contact thermal sensors measure temperature by converting infrared energy radiated from target objects into heat with MEMS thermopiles and then measuring the thermoelectromotive force resulting from temperature differences that occur across the contact points of two different types of metal. However, up till now it has not been possible to create large temperature differences across the metal contact points because much of the heat generated by the thermopiles dissipates into the surrounding air, meaning that the resulting thermoelectromotive force is reduced thereby limiting sensitivity. OMRON has solved this heat dissipation problem by vacuum sealing the thermopiles inside the chip - the first time this has been achieved. The reduction in heat dissipation leads to a greater temperature difference across the metal contacts thereby increasing sensitivity.

OMRON will now also work on commercializing stand-alone human presence sensor modules by combining non-contact thermal sensors with algorithms that can accurately distinguish the number of people and their positions within a detected space.

Model versions of OMRON's new human presence sensors will be displayed at the "Nanomicro Biz" Exhibition at Tokyo Big Sight on July 3, 4, and 5.

The development of this new sensor was the result of research carried out in collaboration with Japan's New Energy and Industrial Technology Development Organization.

* As of May 29, 2013, according to OMRON's own research on MEMS non-contact thermal sensors.

Features

- The ability to detect motionless people thanks to the use of thermopile-based sensors, unlike pyroelectric sensors that can only detect people when they are moving.

- Improved accuracy of detection of people's positions within the target space with thermal sensing possible over a two-dimensional 256 pixel (16x16 element) area.

- Wide 90-degree field of view means that one sensor can be used to cover a space that would require four 45-degree sensors to cover.

- High-speed 4fps detection (4 frames per second) makes it possible to detect people moving at 1m/s.

Sensor exterior

Specifications/Performance

| Number of elements | 16x16 |

|---|---|

| Detectable target temperature range | 5-50 degrees Celsius |

| Field of view | 90 degrees minimum |

| Power supply voltage | DC2.7 to 5.5V |

| Data transmission | SPI |

| Temperature resolution (NETD) | 0.15 degrees Celsius |

| External dimensions | W 20mm x L 37mm x H 10.7mm |

Release date

October 2013 (test samples)

Sales target

2 billion JPY in fiscal 2015

How non-contact thermal sensors work

Thermal sensors utilize the Seebeck effect in which thermoelectric force is generated due to the temperature difference at the contact points between two different kinds of metal. Thermopiles are created by serially connecting thermocouples consisting of N+ poly Si, P+ poly Si, and Al. By creating hot junctions on highly heat-resistant dielectric membranes, and cold junctions on highly heat-conductive silicon, it is possible to achieve high-energy conversion efficiency. Sealing thermopiles in a vacuum prevents the heat they create from dissipating into the air thereby increasing sensitivity.

About OMRON

Headquartered in Kyoto, Japan, OMRON Corporation is a global leader in the field of automation. Established in 1933, OMRON has more than 35,000 employees in over 35 countries working to provide products and services to customers in a variety of fields including industrial automation, electronic components, social systems, healthcare, and the environment. The company has regional head offices in Singapore (Asia Pacific), Beijing (Greater China), Amsterdam (Europe, Africa, and the Middle East), Chicago (the Americas), Gurgaon (India), and Sao Paulo (Brazil).

For more information, visit OMRON's website at https://www.omron.com/

- Contact

- OMRON Corporation

Business Management Division HQ Sensing & Module Division.

Electronic and Mechanical Components Company

TEL:+81-75-344-7148