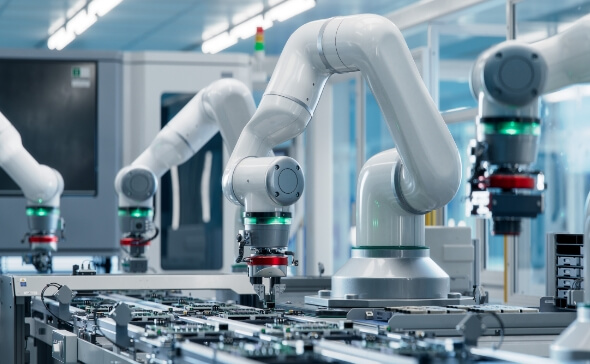

Sensors and controllers to improve productivity and quality at manufacturing sites.

Safety components indispensable in improving the safety of manufacturing sites.

Our aim is to help factories be safer and more efficient, and to do that we are providing software that can be incorporated into these devices.

We also build a foundation to make safe and secure use of the large amounts of data found on worksites, so that we can provide solutions to solve the various problems our customers face.

We will continue to contribute to the future of manufacturing sites through new software technologies we create.

We develop and provide software to be embedded into FA control equipment that can help realize productivity, quality, and safety improvements for manufacturing site automation lines.

We are contributing to the automation of factories by providing software to be embedded into the various sensors, controllers, network equipment and more that make up the FA system.

We provide solutions that protect important and valuable data at manufacturing sites with safe and secure systems, and provide real work instructions and support by remotely connecting on-site engineers with experts who have the know-how to solve problems that may occur on worksites.

We collect, analyze, and make use of the various production and quality data generated in automated lines, cell assembly lines, etc., to provide system solutions for real-time production instructions, estimating the causes behind defects, predicting occurrences of defects, and more.

We will support improvements in the convenience of safe and comfortable stations with reliable software technology.

We will create the future of manufacturing sites by utilizing the most advanced technologies such as AI and IoT.

Supporting a next generation electronic payment society through advanced software technology.

Contributing to the development of diversifying financial systems through reliable software technology.

Utilizing proprietary language processing technology to create a comfortable communication society.

Contributing to the realization of healthy lives for people through software technology.

We will promote DX in society and help to create a prosperous future as experts in the use of digital technology.