OUR TECHNOLOGY

This is one of the principles that OMRON founder Kazuma Tateishi advocated for as he worked toward innovation driven by social needs, creating the worldŌĆÖs first unmanned railway station system and other innovations based on revolutionary technology.This is the bedrock of OMRONŌĆÖs R&D strategy as we continue to shape the future.

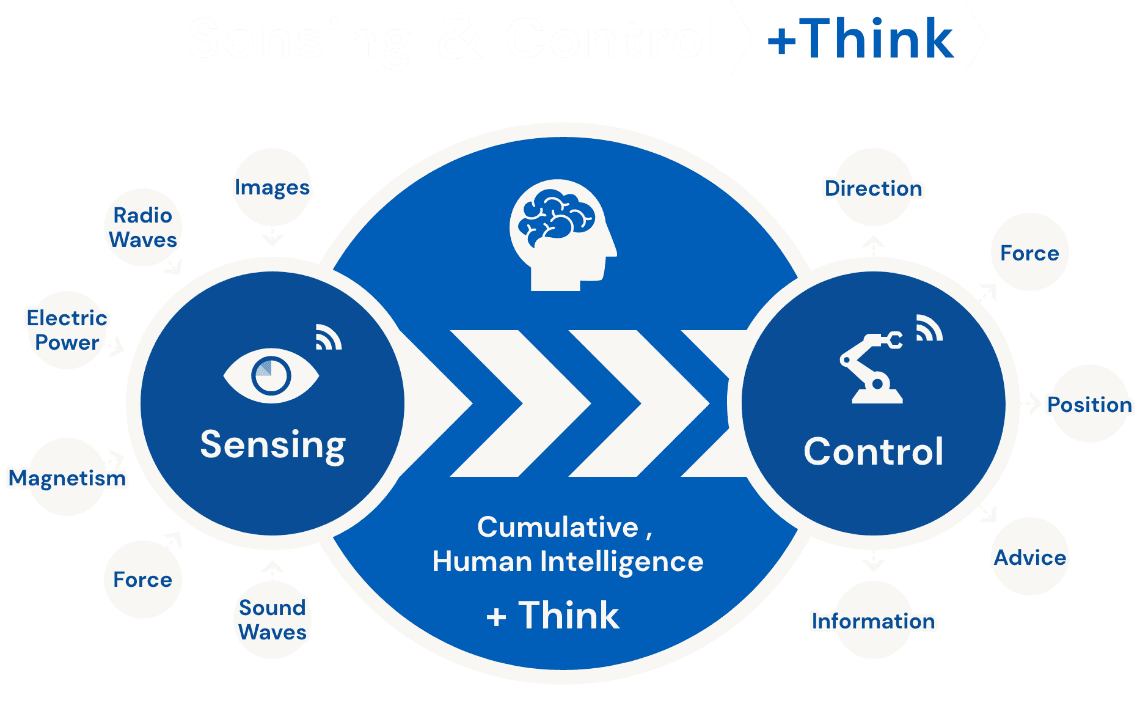

ŌĆ£Sensing & Control + ThinkŌĆØ represents OMRONŌĆÖs core proprietary technologies.

To create value that ushers in each new era, OMRON constantly evolves these unique technologies.

News

Nov.26,2025

News

Aug.25,2025

News

Jul.11,2025

News

Feb.26,2025

News

Nov.26,2025

News

Aug.25,2025

News

Jul.11,2025

News

Feb.26,2025

News

Nov.26,2025

News

Aug.25,2025

News

Jul.11,2025

News

Feb.26,2025