The year 2020 will be remembered for the distancing--both physically and psychologically--between companies and their employees throughout the world, as working from home became the norm in the wake of the COVID-19 pandemic. In what has become a "new normal" work style, where working solo has become commonplace, many may have found themselves questioning, "What do I work for?" or "What do I wish to realize through work?" As more corporate employees work from home, it will be harder to give careful attention to detail compared to the previous norm when people used to communicate face-to-face without any restrictions. Against this backdrop, it will be increasingly important for us all to have a sense of purpose in our work and think and act for ourselves.

Presented in this edition of Edge & Link is a story of the development of an "active prosthetic leg," a project initiated by young engineers at OMRON's manufacturing factory in Indonesia out of their desire to help their fellow workers with lower limb amputations, which was later developed into a full-fledged business.

Located about 44 kilometers from the capital city of Jakarta, PT OMRON Manufacturing of INDONESIA (OMI) manufactures industrial machinery and electronic and mechanical components for use in home appliances and other electronics. In 2006, OMI began aggressively recruiting persons with disabilities for production jobs; now, 35 out of their 2,541 employees have some form of disability. Following in the footsteps of OMRON Founder Kazuma Tateishi, who believed in the empowerment of persons with disabilities, OMI is putting into practice "Respect for All," one of the values upheld in the OMRON Principles.

A production engineer at OMI, Fathian Hafiz Aulia knew how hard it was for his fellow employees with disabilities to lead their daily lives and was profoundly impressed by their devotion and dedication to work.

Things were particularly challenging for associates who have a lower limb amputation for one reason or another. Just standing or squatting to get production equipment ready or moving between different production equipment is very demanding for them. Also, Indonesia has a large Muslim population for whom offering prayers five times a day is extremely important. Yet, dropping on their knees or sitting on their heels can be tremendously strenuous. Fathian recalls how he felt in those days, "I could clearly see that they were very passionate and proud of what they were doing. Naturally, I began asking myself how I could support them in a way that would enhance their quality of life and keep their passion alive while letting them demonstrate their individuality." Out of this desire, Fathian began seeking ways to help his associates who had a lower limb amputation.

Fathian started by sharing his passion with his peers to begin forming a team. Initially, he was not without concern, thinking, "What if no amount of persuasion will earn a thumbs-up for my idea?" Yet, he took a chance and shared his plan with others and quickly discovered that one of his peers happened to have studied prosthetic legs at university. Then, one associate with an amputated leg from Fathian's department, as well as three other associates, including an experienced senior associate, joined him to form a like-minded team of five.

The five met frequently to discuss how they could realize Fathian's wish to help his associates. They concluded that the best solution would be to develop an active prosthetic leg that is affordable for anyone because there were major problems for prosthetics in Indonesia.

Indonesia has as many as three million persons who have a lower limb amputation, many of whom use simplified prosthetic legs that are lacking functionality but with a focus on their visual appearnce. Use of these prosthetic legs would often result in issues such as pain and fatigue, and difficulties in walking due to lack of flexibility. Meanwhile, prosthetics equipped with an electric motor and made to be flexible and comfortable to wear cost 70,000 U.S. dollars there, which is about 600 times the average salary of persons with disabilities in Indonesia. Such a price tag obviously limits the number of people that can afford them.

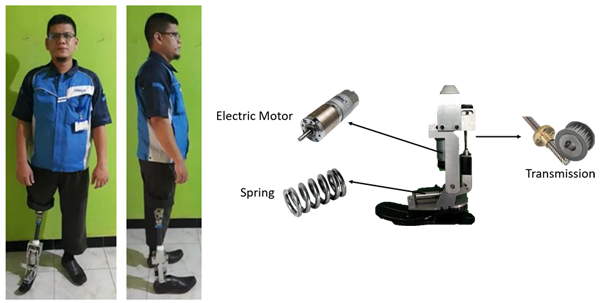

Thus, Fathian and his team decided to make an inexpensive "active prosthetic leg," using components like electric motors, transmissions, springs, and other components, in a bid to address these challenges. "We manufacture production equipment for OMRON plants. So, it occurred to me that I might try manufacturing machines that assist those associates who support manufacturing on the shop floor. I just wanted to be of use to the associates whom I had the pleasure of working with," recalls Fathian. In 2018, the five kicked off the project to develop active prosthetic legs.

At the outset, however, Fathian's team of five struggled to make progress.

They began by assembling a prototype, but something was not right. OMI specializes in manufacturing components for production equipment. It is thus natural that they do not know how to simulate human ambulation, repetition of which is essential to design prosthetic legs that comfortably move in accordance with human movement. Another thing they found was that sourcing all components in-house was not enough to offer affordable prices for all. "What can we do to reduce costs without compromising quality?" was the question that troubled Fathian day in and day out. "Can we really proceed with this challenging project in parallel with our actual jobs? It was clear we would reach a dead-end if we were to continue with just the five of us," he confesses.

To break this impasse, Fathian made a move to solicit support for the development of active prosthetic legs: he petitioned OMI's management to ask for their official approval of the project. In speaking to management, he stressed the fact that the project would resonate with OMRON's Mission, "To improve lives and contribute to a better society," as well as OMI's vision, "To realize a society where persons with disabilities can give full play to their abilities and individuality." Fathian went on to say that he wanted to help not only those working at OMI but also the more than three million people with lower leg amputations in Indonesia. "To make this happen, I desperately needed OMI's resources and helping hands from outside partners. I was overjoyed when they readily consented to my request. Under the auspices of the company, I was able to take on various challenges with everything we could muster," says Fathian.

A brainchild of five employees who wholeheartedly wished to help their fellow workers with disabilities, as well as to enhance the well-being of those with disabilities in the Indonesian society, complete with input from OMI's management, the active prosthetic leg was aptly named "Bionic Leg to Empower and Support Society (B.L.E.S.S.)," and full-scale development progressed.

With the company's seal of approval, it became easier to ask for cooperation from various parties, which helped solve pending issues one after another. In the realm of technology, for example, it became within their reach to develop a walking machine using componets made in-house such as servomotors and motor drivers as well as programmable logic controllers (PLCs) and switches for controlling production equipment and repeat walking tests, which enabled them to develop much-needed simulation software that reproduces human ambulation. On the cost front, with cooperation from local component suppliers, the distribution cost was reduced by 50%. Also the team is now in the process of approaching foundations, NGO, and insurance companies to persuade them to join as sponsors so that the product can be produced in large quantities. Those supporters had established a lasting relationship with OMI through business and knew that OMI was proactive in hiring persons with disabilities. They readily endorsed the project and promised steadfast support.

In 2019, one year after the commencement of the project, the first prototype of B.L.E.S.S. became a reality. Those who tried the prototype developed by Fathian's team gave it high marks, claiming that B.L.E.S.S. was more flexible, had a wider range of motion, and fit better than any other prosthetic leg they had used.

This is not the end of the story, and Fathian's challenge continues to expand. Various stakeholders both within and outside the Group, including the division coordinating the new business creation for the entire Group and universities in Indonesia, offered their cooperation when they came to know about Fathian's team's project.

To wrap up the journey of the five young employees so far, Fathian looks back on the past 3 years, considering the turning points where they gathered momentum toward commercialization and their self-growth: "Guided by its Principles, OMRON aims to contribute to social development through business. This corporate culture has filtered onto the manufacturing floor. Amidst this backdrop, a group of pure-hearted young engineers who did not hesitate to express their passion entered the picture. As we gained empathy from diverse stakeholders, the project gathered speed. We began with one ardent desire to be of help to fellow workers with a lower limb amputation. As we proceeded, however, we came to see the magnitude of social issues that needed to be addressed, such as improvement of self-esteem and creation of equal job opportunities, in addition to the functionality of prosthetic legs, which further enhanced our passion for and sense of responsibility toward the project."

Solving social issues through business in a way that the OMRON Principles dictate is OMRON's raison d'├кtre. As each and every employee assimilates the OMRON Principles deeply, takes autonomous action to address social issues on their own volition, and challenges themselves, they foster a circle of empathy and resonance, which then expands outside the Group to create even greater value. Going forward, OMRON will remain committed to solving social issues as we put the OMRON Principles into practice.