![]()

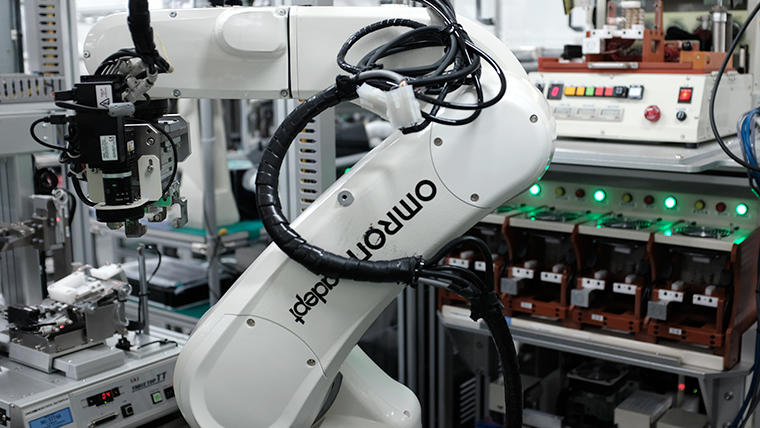

OMRON Industrial Automation business envisions the creation of future manufacturing sites where humans and machines work together in harmony. Our factories also focus on productivity quality innovation. With the "FROM THE FACTORY OF THE WORLD" series, we will introduce these OMRON factories from around the world one at a time.

In this first issue of the series, we will introduce OMRON's largest, the OMRON Shanghai factory.

The Shanghai factory, launched in Shanghai, China, in 1994, has now grown to make up the core of manufacturing in the industrial automation business. Where is the factory heading in the future?

We interviewed Shinji Mizuno, Strategy Planning Headquarter Manager at OMRON Shanghai.

It was in 1994, more than 20 years ago, that OMRON began production in Shanghai. Back then, there were only a few Japanese companies who had advanced into China, and we were among the first to start business there. At that time, we manufactured three types of products in our factories: programmable logic controllers (PLC), sensors, and timers. In 2005, these factories were integrated to achieve internationally competitive manufacturing capabilities, and with the establishment of the second factory in the same premises in 2018, the Shanghai factory has gradually expanded its scale. Of the four factories, in Kusatsu, Ayabe, the Netherlands, and Shanghai, the Shanghai factory is the largest, manufacturing almost all category of OMRON Industrial Automation business's product models.

"The Shanghai factory is not merely a manufacturing site built for the purpose of mass production. As anticipated at the time of the factory integration in 2005, personnel costs have been increasing at a rate of several percent per year, as originally forecasted. If it's just a manufacturing site, it doesn't need to be in Shanghai," says Mizuno.

Then why run the factory in Shanghai, rather than elsewhere in China, if there is no advantage in terms of personnel costs?

Mizuno explains, "That's because we set our eyes on "China as a market."

"Today, we ship half of the products manufactured in the Shanghai factory to mainland China, and the other half to the rest of the world. But in the future, we expect demand in China to further increase. And so we built the Shanghai factory with R&D capabilities, and established the Automation Center to allow us to help customers solve their problems while working on actual model machines installed in front of us, as an annex to further promote co-creation with our customers in the Chinese market."

Mizuno continued by saying, "The strength of our Shanghai factory lies in its horizontal deployment capabilities and commercial application capabilities."

"For example, although our Kusatsu and Ayabe factories in Japan can arrange ten production lines at each factory, our Shanghai factory can build ten times more lines, or 100 production lines. On top of that, it has further technologies and know-how that we have acquired through experience."

The OMRON Automation Center has model machines with typical mechanical systems. At the Center, we can demonstrate control technologies with real equipment and hold technology exchange meetings, allowing us to make more specific suggestions and provide more tailored support for our customers' problems.

The OMRON Automation Center has model machines with typical mechanical systems. At the Center, we can demonstrate control technologies with real equipment and hold technology exchange meetings, allowing us to make more specific suggestions and provide more tailored support for our customers' problems.At the OMRON Shanghai factory, we have been working on various initiatives since its establishment.

Many of these initiatives are deployed in our factories in Kusatsu, Ayabe, and the Netherlands, and the speed of our horizontal deployment capabilities contributes to OMRON's strengths.

These factory initiatives are applications of OMRON's "innovative-Automation". OMRON work to improve manufacturing sites through the principles of integration, intelligence and interactivity.

See below for more information on "innovative-Automation":

https://www.omron.com/innovation/manufacturing.html

* "innovative-Automation" is OMRON's concept name for the value provided by our solutions.

Meanwhile, Mizuno says the factory is facing difficulties unique to China.

"Specifically, there are significant fluctuations in demand, and rising labor costs, as I mentioned earlier. For example, although the sales of automobiles in China are the highest in the world, the number of vehicles sold dropped sharply from September due to the great impact of political and economic developments on the manufacturing industry. In addition, Chinese society has become increasingly affluent over the last decade, and the values of the people working there are changing rapidly," explains Mizuno.

The goal of the OMRON Shanghai factory is to achieve greater flexibility and productivity, while enriching people around the world by "Made in China".

Mizuno concluded by saying, "By putting "innovative-Automation" into practice, OMRON will continue contributing to enriching the lives of people in Chine and around the world."

The OMRON Shanghai factory will strive for continued growth.